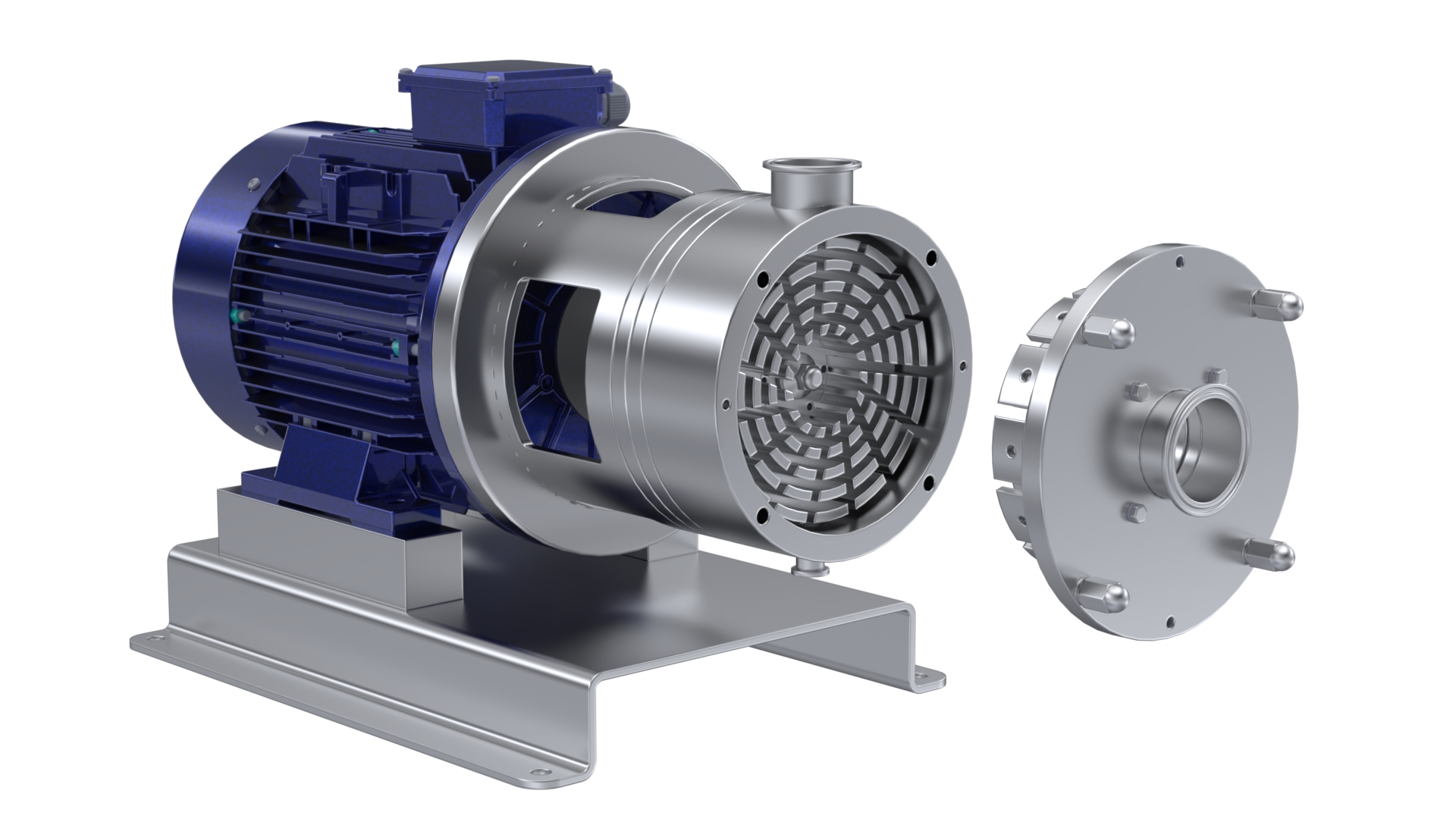

Inline Mixer

Inline Mixers for great performance

The inline mixers provide high emulsion grades and are able to pump the product thanks to their slotted head and propeller design. These mixers achieve a completely homogenised, lump-free product and prevent oxidation.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Inline Mixer Application

The casing is similar to a casing of a centrifugal pump, it houses the stator and the rotor. It is characterised by a high shear due to an adjusted tolerance between the rotor and the stator.

The product is suctioned through the inlet and the rotor pushes it to the stator. inline mixer. Passing through the slots of the stator the product is mechanically sheared, the particles are sheared. If the viscosity of the product is higher than 200cP, it is recommended to put an auxiliary.

Inline Mixer Options

Disintegrating head. Fine screen head.

Disintegrating head. Fine screen head.- Cooled or pressurised mechanical seal.

- Connections: DIN 11851, SMS, flanges, etc:

- Baseplate with antivibration legs.

- Trolley with/without control panel.

- Mirror polish Ra < 0.5 um for the pharmaceutical applications.

- Other motor protections.

Inline Mixer Operation

The casing is similar to a casing of a centrifugal pump, it houses the stator and the rotor. It is characterised by a high shear due to an adjusted tolerance between the rotor and the stator. The product is suctioned through the inlet and the rotor pushes it to the stator.

Passing through the slots of the stator the product is mechanically sheared, the particles are sheared. If the viscosity of the product is higher than 200cP, it is recommended to put an auxiliary.

User Benefits

- Fast and homogenous powder dissolving A combination of a stationary inline powder-liquid mixer and a pump

- High dynamic shear, gentle mixing

- Easy maintenance

- Reduced installation, emissions, energy and maintenance costs

- Reduced total cost of ownership combining the functions of Powder mixing and pumping into a single unit

Downloads & Documents

Inline Mixer Inquiry Form

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.