Bottom Side Entry Agitators for great performance

SKYR & SKYM Bottom Side Entry Agitators are highly suitable for maintaining and mixing products in medium and large volume vessels.

This models are installed in the bottom of the vessel, slanted to obtain the optimum mix ratio. The shaft length, diameter and propeller type are selected with this same purpose. All this, along with the mechanical sealing system in the shaft, allows these agitators to offer high performance and durability.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Application

The side entry agitators are used in process and storage tanks in the applications of the food-procesing industry.

The main application is the agitation of low viscosity products like wine, oil, milk, beer, alcohol, etc. in large volume tanks

Operation

These Bottom Side Entry Agitators are installed in a inclined position. The rotation of the propeller creates a flow that impales the product to the bottom of the tank and then raises up to the surface along the wall opposite to the agitator. The effect is promoted if the bottom is curved. The agitator is installed decentralized to enhance the circular flow. Thus a complete homogenization of the product is achieved.

Technical Specifications of Bottom Side Entry Agitators

Materials

Parts in contact with the product: AISI 316L

Lantern and bearing support: GG 15

Mechanical seal: C/Sic/EPDM

Gaskets: EPDM

Surface condition: Ra ≤ 0.8 µm

Options

- Double flush mechanical seal.

- Plastic coated shaft and propeller for use with corrosive media.

- Welded propeller with surface finish Ra ≤ 0.5 µm.

- Motor housing.

- Motors with other protections.

- Seal: Viton

- Various propeller types.

- ATEX motor.

- High flow rate propeller.

- User benefits

- Versatile, modular and hygienic design

- Can be configured for minimum energy consumption

- Gentle product handling

- Higher availability and higher yields due to low maintenance

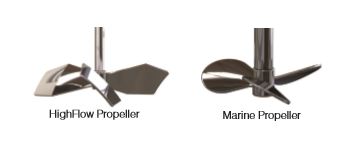

Propeller Type

The design of the propeller have a decisive influence on the process engineering and mechanical properties.

Thanks to specific design of HighFlow propeller , it can be used when the tank volume is bigger thank 200 m3. Compared to other conventional propeller , it pumps more flow and delivers more energy to fluid with low power consumption. Bottom Side Entry Agitators

Bottom Side Entry Agitators Selection Parameters

| Type | Flow (m³/h) | Tank Volume (m³) | Power (kw) | Speed (rpm) | Weight (kg) |

| SKYR 02-05-325 | 243 | 5-20 | 0,55 | 200 | 55 |

| SKYR 02-07-400 | 455 | 20-50 | 0,75 | 58 | |

| SKYR 02-15-500 | 915 | 50-100 | 1,50 | 65 | |

| SKYR 02-30-600 | 1550 | 100-150 | 3,00 | 78 | |

| SKYR 02-40-650 | 1973 | 150-200 | 4,00 | 136 |

| Type | Flow (m³/h) | Tank Volume (m³) | Power (kw) | Speed (rpm) | Weight (kg) |

| SKYM 15-15-175 | 275 | 5-20 | 1,5 | 1500 | 47 |

| SKYM 15-30-200 | 415 | 20-50 | 3,0 | 57 | |

| SKYM 15-55-225 | 815 | 80-140 | 5,5 | 67 | |

| SKYM 15-75-250 | 1081 | 80-140 | 7,5 | 76 | |

| SKYM 15-11-275 | 270 | 140-200 | 11,0 | 146 | |

| SKYM 10-01-200 | 385 | 5-20 | 1,1 | 1000 | 49 |

| SKYM 10-22-225 | 555 | 20-60 | 2,2 | 63 | |

| SKYM 10-30-250 | 715 | 20-60 | 3,0 | 67 | |

| SKYM 10-40-275 | 935 | 60-90 | 4,0 | 76 | |

| SKYM 10-55-300 | 1455 | 90-150 | 5,5 | 151 | |

| SKYM 10-75-350 | 1455 | 150-200 | 7,5 | 183 |

User Benefits

- Versatile, modular, hygienic design

- Can be configured for minimum energy consumption

- Gentle product treatment

- More uptime and higher yields due to low maintenance

Downloads & Documents

Bottom Side Entry Agitators Inquiry Form

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.