Chocolate Pumping for great performance

Chocolate Pumping is one of the most difficult fluids to transfer in food production. With its ever-changing and shear sensitive properties, it must be handled with extreme care.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Chocolate Pumping Application

Chocolate is one of the most difficult fluids to transfer in food production. With its ever-changing and shear sensitive properties, it must be handled with extreme care. If a user is struggling with consistency and quality of chocolate, talking to an engineer experienced in the subject is a good idea. We will be able to help users easily to increase your production and reduce chocolate-induced your headaches with our experience.

The pumping chocolate (also compound chocolate, creams, and cocoa paste) is a delicate process.. It is shear sensitive, viscous, solidifies when cool and also requires special attention to hygiene . We use specially designed mechanical seals in our pumps in order to avoid leakage problems.

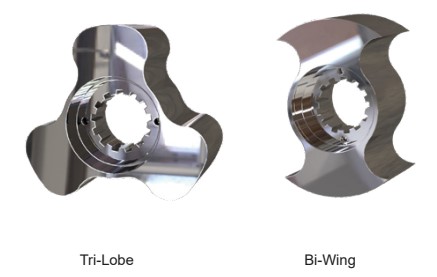

Chocolate will be shear sensitive, if pumped at high speeds.It is important to select suitable chocolate pumps, as the viscosity of the fluid can be very high. Depending on the user’s goals lobe are one of the best choices for chocolate. We recommend using lobe pumps . they are hygienic and easy to clean, as well as being able to pump high-viscosity products efficiently.

Lobe pumps are more complex but provide solids handling capability for chocolates containing ingredients like peanuts or raisins.

We put on attaching a heating jacket to the front cover and/or the pump body to keep the chocolate warm and prevent it from solidifying inside the pump.

User Benefits

- Hygienic Design

- Low energy consumption

- Compact size

- Smooth flow

- Reversible operation

- Low shear pumping

- Minimal pumped media agitation

- Easy maintenance

Operation

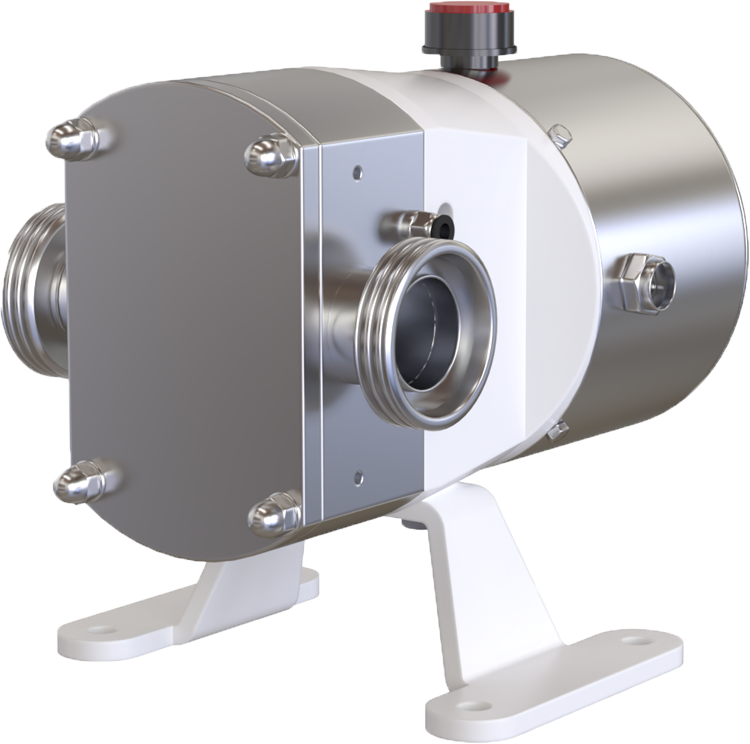

The positive displacement of the Series SLA pump is provided by non-contacting, contra-rotating two or tri-lobe rotors within a fully swept pump chamber.

Technical Specifications

Materials

Pump Head Housing: AISI 316L

Gaskets: EPDM or FPM

Gear Box: GG25

Shafts: Duplex Stainless Steel

Shaft Seal: Single,Double Mechanical Seal

Surface Finish: Ra<0,8 μm

Connections: DIN 11851, SMS, ISO, Clamp

Base Plate: Stainless Steel

Coupling Guard: Stainless Steel

Operating Limits

Maximum flow: 15 m3/h

Maximum differential pressure: 12 bar

Maximum working pressure: 12 bar

Temperature range (EPDM): -10 °C to +120 °C

Temperature CIP, max. 30 min: +140 °C

Maximum speed: 120 rpm

Downloads & Documents

Chocolate Pumping Inquiry Forms

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.

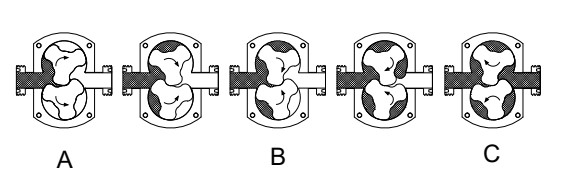

Lobes Type

SLA rotary lobe pumps basically consist of two lobe rotors which rotate synchronously inside a casing without touching each other.

As the rotors rotate, the spaces between the lobes and the casing are filled with the product, which is transported to the discharge nozzle with a fixed amount of displacement.

The pumped fluid forms a continuous stream thanks to the tolerances between the lobes and the pump casing, this ensuring an efficient pumping.

Chocolate Pump

Chocolate is one of the most difficult fluids to transfer in food production. With its changing and shear-sensitive properties, it must be handled with extreme care. If a user is faced with problems with the consistency and quality of chocolate, it is best to contact an engineer experienced in this matter. With our experience, we will be able to help users increase their production and reduce chocolate headaches.

Chocolate is one of the most difficult fluids to transfer in food production. With its changing and shear-sensitive properties, it must be handled with extreme care. If a user is faced with problems with the consistency and quality of chocolate, it is best to contact an engineer experienced in this matter. With our experience, we will be able to help users increase their production and reduce chocolate headaches.

Chocolate Pumping (also composed of chocolate, creams, and cocoa paste) is a delicate process. It is shear sensitive, viscous, solidifies when cooled and also requires special attention to hygiene. We use specially designed mechanical seals in our pumps to avoid leakage problems.

Chocolate is sensitive to shear if pumped at high speeds. It is important to choose suitable chocolate pumps, as the viscosity of the fluid can be very high. Depending on the user’s goals, lobe pumps are one of the best choices for chocolate. We recommend the use of lobe pumps: they are hygienic and easy to clean, and allow high viscosity products to be pumped efficiently.

Lobe pumps are more complex, but can handle solids for chocolates containing ingredients such as peanuts or raisins.

We suggest attaching a heating jacket to the front cover and/or body of the pump to keep the chocolate hot and prevent it from solidifying inside the pump.