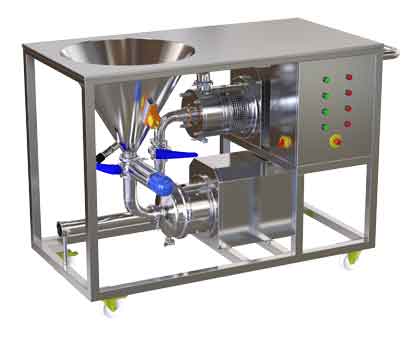

SB300 / SBM300 Table Blender for great performance

The SB300 / SBM300 table blender can be used in order to dissolve powder into solid. It has a wide variety of application areas such as preparation of pharmaceutical syrops and pectin in glucose for marmelade production.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Table Blenders Application

The SB300 / SBM300 table blender can be used in order to dissolve powder into solid. It has a wide variety of application areas such as preparation of pharmaceutical syrops and pectin in glucose for marmelade production. In-line mixer can be included in system to handle with difficult mixing. The typical applications are reconstitution or stabilization of milk in the production of dairy products, and dissolution of sugar for the production of syrup in the beverage industries.

Table Blenders Operation

Table blender consist of a centrifugal pump with a ventury system at the suction side and hopper with a butterfly valve. The suction and ventury system are set horizontally. For difficult mixing, an inline mixer can be included after the centrifugal pump to reduce the size of possible lumps.

When the valve of the hopper opens, the solids are drawn from the hopper and are totally dissolved when they pass through the casing of the pump.

Materials

Parts in contact with the product: AISI 316L

Other steel parts: AISI 304

Gaskets in contact with the product: EPDM

Internal and hopper: Bright polish Ra ≤ 0,8 μm

Mechanical Seal

Rotary part: Silicon carbide (SiC)

Stationary part: Silicon carbide (SiC)

Gaskets: EPDM

Hygienic design.

ISO 2852 Clamp connections for easy assembly/disassembly.

Cleaning and disinfection without disassembling the unit.

Complete mixing with recirculation.

Manually actuated butterfly valve for hopper.

Hopper welded to the table with a totally smooth easy-to-clean surface.

SS control panel with Stop/Start button and motor protection.

Skid with wheels: 2 rotating + 2 fixed with brakes.

Triphasic induction motor with B5 flange and B3 legs, in compliance with the IEC standards,

2 poles = 3000/3600 rpm, efficiency class according to EC regulation,

IP 55 protection and F-class insulatio

Options

- Double mechanical seal.

- Solenoid valve for the seal cooling system.

- Gaskets: FPM or PTFE.

- Connections: DIN, SMS, CLAMP

- Vibrator for hopper.

- Frequency converter for the centrifugal pump.

- Pneumatically actuated valve + lower level sensor for solids.

- Hygienic upper level sensor for solids.

- Control panel for the vibrator, level sensors, frequency converter and automated valve.

User Benefits

- Hygienic Design

- Cleaning and disinfection without disassembling the unit

- Very simple and effective equipment for homogeneous mixing

- Fast powder dissolving

- High dynamic shear

Downloads & Documents

Table Blender Inquiry Form

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.

Table Blenders Operating Data

| Type | Centrifugal Pumps |

In-line mixer | Flow (m3/h) | Solid Capacity* (kg/h) | Hopper (L) | |||

| Power (Kw) | Power (kw) | Sugar up to 250 brix | Sugar up to 50 brix | Milk powder 20 % | Thickener up to 400 cP | |||

| SB-300-1 | 3 | – | 25 | 1650 | 1350 | 950 | 300 | 45 |

| SBM-300-1 | 4 | |||||||

| SB-300-2 | 7,5 | – | 40 | 3700 | 2400 | 3300 | 650 | 45 |

| SBM-300-2 | 7,5 | |||||||

| SB-300-3 | 18,5 | – | 95 | 12800 | 8900 | 9200 | 600 | 75 |

| SBM-300-3 | 18,5 | |||||||