Heat Exchangers

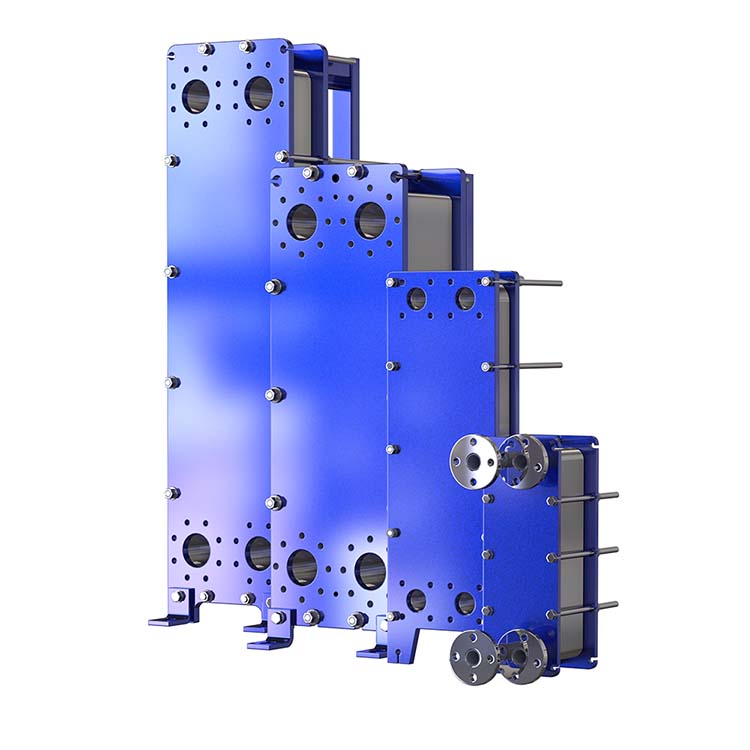

A gasketed plate heat exchangers (PHE), also known as a plate-and-frame heat exchanger, is a type of heat exchanger that consists of a series of metal plates with gaskets sandwiched between them. The plates are typically made of stainless steel or titanium and have corrugated patterns that create channels for the flow of fluids.

HEAT EXCHANGERS

HEAT EXCHANGERS

Gasketed plate heat exchangers are commonly used in various industries for heat transfer applications, such as heating, cooling, and heat recovery processes. They are efficient and compact, offering a large heat transfer surface area within a relatively small footprint. The corrugated patterns on the plates promote turbulence and enhance heat transfer efficiency.

One of the advantages of gasketed plate heat exchangers is that they allow for easy maintenance and cleaning. The individual plates can be removed, inspected, and cleaned without disassembling the entire unit. This makes them convenient for applications where regular maintenance or occasional inspection is required.

It’s important to note that gasketed plate heat exchangers are just one type among various heat exchanger designs available, each with its own advantages and limitations. The selection of a heat exchanger depends on factors such as the specific application requirements, operating conditions, fluid properties, and available space.

Where are Plate Heat Exchangers used?

Plate Heat Exchangers (PHEs) are used in various industries due to their efficiency, compact size, and ability to handle high heat transfer rates. Some common applications include:

- HVAC & Refrigeration

- Chilled water systems

- Heat recovery systems

- District heating and cooling

- Food & Beverage Industry

- Pasteurization (milk, juice, beer, etc.)

- Dairy processing

- Brewery cooling

- Power Plants & Energy Sector

- Waste heat recovery

- Cooling of lubricants and transformer oils

- Condensers in steam turbines

- Chemical & Pharmaceutical Industry

- Process heating and cooling

- Solvent recovery

- Temperature control in chemical reactions

- Marine & Automotive Industry

- Engine cooling

- Oil coolers

- Waste heat recovery

- Industrial Manufacturing

- Metal processing

- Plastic and rubber manufacturing

- Textile dyeing processes

Their ability to provide efficient heat transfer in a compact design makes them a preferred choice over traditional shell-and-tube heat exchangers in many applications.