[vc_row mobile_bg_img_hidden=”no” tablet_bg_img_hidden=”no” woodmart_parallax=”0″ woodmart_gradient_switch=”no” row_reverse_mobile=”0″ row_reverse_tablet=”0″ woodmart_disable_overflow=”0″][vc_column width=”1/6″][/vc_column][vc_column width=”1/3″]

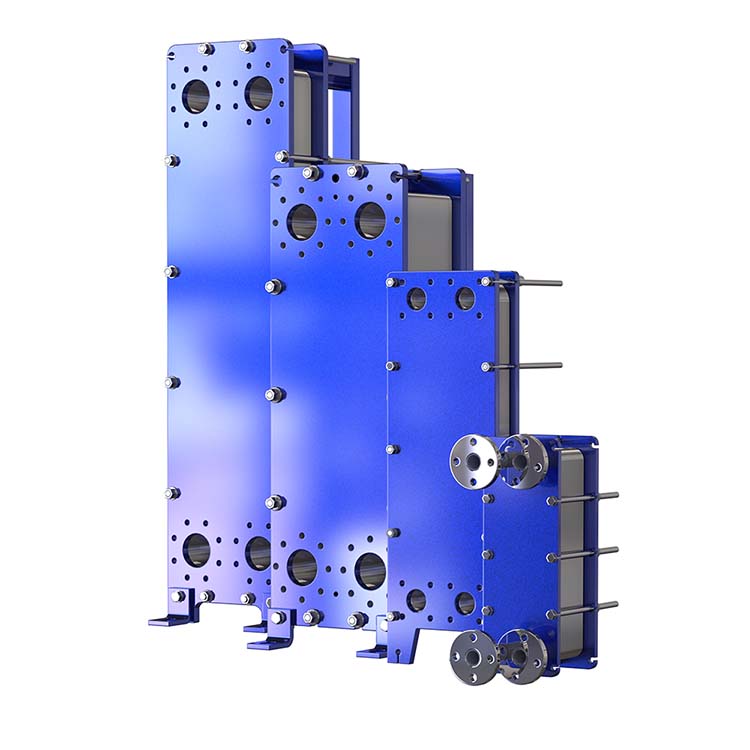

[/vc_column][vc_column width=”1/3″][vc_empty_space woodmart_hide_large=”0″ woodmart_hide_medium=”0″ woodmart_hide_small=”0″][vc_custom_heading text=”Gasketed PHE for great performance” font_container=”tag:h2|text_align:left|color:%23182d77″ use_theme_fonts=”yes”][vc_column_text css=”” woodmart_inline=”no” text_larger=”no”]The Gasketed Plate Heat Exchanger is essential for efficient heat transfer in industrial applications. Its design allows for easy maintenance and scalability, making it a cost-effective solution. The gaskets provide a reliable seal, preventing leaks and ensuring optimal performance.

[/vc_column_text][/vc_column][vc_column width=”1/6″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”4939″ alignment=”center” title=”Dairy” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][vc_column width=”1/6″][vc_single_image image=”4941″ alignment=”center” title=”Cosmetic” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][vc_column width=”1/6″][vc_single_image image=”4942″ alignment=”center” title=”Food” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][vc_column width=”1/6″][vc_single_image image=”4943″ alignment=”center” title=”Pharmaceutical” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][vc_column width=”1/6″][vc_single_image image=”4944″ alignment=”center” title=”Brewery” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][vc_column width=”1/6″][vc_single_image image=”4945″ alignment=”center” title=”Syrups” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][/vc_row][vc_row][vc_column width=”3/4″][vc_column_text css=”” woodmart_inline=”no” text_larger=”no”]

Gasketed Plate Heat Exchanger Application

The Gasketed plate heat exchanger also called plate and frame plate heat exchanger consists of a pack of corrugated metal plates. The corrugation of the plates provides the passage between the plates, the two fluids transfer the heat between the channels. The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The gasket between the plates seals the inter plate channel and directs the fluids into alternate channels. The number of plates is determined by the design: the temperature program, flow rate, pressure drop and physical properties of the fluids,. The plate corrugations promote fluid turbulence and the plate contact point support the plates against pressure. The fix frame plate and the movable frame plate are fixed to a support column. Connections are located in the frame plate or pressure plates, this depends

Gasketed Plate Heat Exchanger Working Principle

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter current flow is created for highest possible efficiency The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Plate Heat Exchanger Portfolio

[/vc_column_text][/vc_column][vc_column width=”1/4″ css=”.vc_custom_1645249750681{border-top-width: 1px !important;border-right-width: 1px !important;border-bottom-width: 1px !important;border-left-width: 1px !important;background-color: #182d77 !important;border-left-color: #182d77 !important;border-left-style: solid !important;border-right-color: #182d77 !important;border-right-style: solid !important;border-top-color: #182d77 !important;border-top-style: solid !important;border-bottom-color: #182d77 !important;border-bottom-style: solid !important;border-radius: 3px !important;}” mobile_bg_img_hidden=”no” tablet_bg_img_hidden=”no” woodmart_parallax=”0″ woodmart_sticky_column=”false” parallax_scroll=”no” mobile_reset_margin=”no” tablet_reset_margin=”no”][vc_empty_space woodmart_hide_large=”0″ woodmart_hide_medium=”0″ woodmart_hide_small=”0″][vc_custom_heading text=”Downloads & Documents” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes”][vc_column_text css=”” woodmart_color_scheme=”light” woodmart_inline=”no” text_larger=”no”]![]() Gasketed PHE (En)

Gasketed PHE (En)

![]() Gasketed Plate Heat Exchangers User’s Manual (En)[/vc_column_text][woodmart_popup style=”bordered” color=”primary” color_scheme_hover=”dark” icon_fontawesome=”fab fa-wpforms” icon_position=”left” id=”contact-form-popup” width=”900″ title=”INQUIRY FORM” woodmart_css_id=”620df1889089a” full_width=”no” button_inline=”no” button_smooth_scroll=”no” bg_color=”eyJwYXJhbV90eXBlIjoid29vZG1hcnRfY29sb3JwaWNrZXIiLCJjc3NfYXJncyI6eyJiYWNrZ3JvdW5kLWNvbG9yIjpbIiBhIl0sImJvcmRlci1jb2xvciI6WyIgYSJdfSwic2VsZWN0b3JfaWQiOiI2MjBkZjE4ODkwODlhIiwiZGF0YSI6eyJkZXNrdG9wIjoiI2ZmZmZmZiJ9fQ==” bg_color_hover=”eyJwYXJhbV90eXBlIjoid29vZG1hcnRfY29sb3JwaWNrZXIiLCJjc3NfYXJncyI6eyJiYWNrZ3JvdW5kLWNvbG9yIjpbIiBhOmhvdmVyIl0sImJvcmRlci1jb2xvciI6WyIgYTpob3ZlciJdfSwic2VsZWN0b3JfaWQiOiI2MjBkZjE4ODkwODlhIiwiZGF0YSI6eyJkZXNrdG9wIjoiI2ZmZmZmZiJ9fQ==”][vc_row_inner equal_height=”yes” css=”.vc_custom_1645189706990{margin-top: -30px !important;margin-right: -30px !important;margin-bottom: -30px !important;margin-left: -30px !important;}” row_reverse_mobile=”0″ row_reverse_tablet=”0″][vc_column_inner width=”2/3″ css=”.vc_custom_1512552766600{padding-top: 30px !important;padding-right: 30px !important;padding-bottom: 15px !important;padding-left: 30px !important;}”][woodmart_title align=”left” size=”small” title=”Gasketed PHE Inquiry Forms” woodmart_css_id=”63067c0c84e57″ responsive_spacing=”eyJwYXJhbV90eXBlIjoid29vZG1hcnRfcmVzcG9uc2l2ZV9zcGFjaW5nIiwic2VsZWN0b3JfaWQiOiI2MzA2N2MwYzg0ZTU3Iiwic2hvcnRjb2RlIjoid29vZG1hcnRfdGl0bGUiLCJkYXRhIjp7InRhYmxldCI6e30sIm1vYmlsZSI6e319fQ==”][vc_column_text css=”.vc_custom_1645860345843{margin-bottom: 0px !important;}” woodmart_inline=”no” text_larger=”no”]

Gasketed Plate Heat Exchangers User’s Manual (En)[/vc_column_text][woodmart_popup style=”bordered” color=”primary” color_scheme_hover=”dark” icon_fontawesome=”fab fa-wpforms” icon_position=”left” id=”contact-form-popup” width=”900″ title=”INQUIRY FORM” woodmart_css_id=”620df1889089a” full_width=”no” button_inline=”no” button_smooth_scroll=”no” bg_color=”eyJwYXJhbV90eXBlIjoid29vZG1hcnRfY29sb3JwaWNrZXIiLCJjc3NfYXJncyI6eyJiYWNrZ3JvdW5kLWNvbG9yIjpbIiBhIl0sImJvcmRlci1jb2xvciI6WyIgYSJdfSwic2VsZWN0b3JfaWQiOiI2MjBkZjE4ODkwODlhIiwiZGF0YSI6eyJkZXNrdG9wIjoiI2ZmZmZmZiJ9fQ==” bg_color_hover=”eyJwYXJhbV90eXBlIjoid29vZG1hcnRfY29sb3JwaWNrZXIiLCJjc3NfYXJncyI6eyJiYWNrZ3JvdW5kLWNvbG9yIjpbIiBhOmhvdmVyIl0sImJvcmRlci1jb2xvciI6WyIgYTpob3ZlciJdfSwic2VsZWN0b3JfaWQiOiI2MjBkZjE4ODkwODlhIiwiZGF0YSI6eyJkZXNrdG9wIjoiI2ZmZmZmZiJ9fQ==”][vc_row_inner equal_height=”yes” css=”.vc_custom_1645189706990{margin-top: -30px !important;margin-right: -30px !important;margin-bottom: -30px !important;margin-left: -30px !important;}” row_reverse_mobile=”0″ row_reverse_tablet=”0″][vc_column_inner width=”2/3″ css=”.vc_custom_1512552766600{padding-top: 30px !important;padding-right: 30px !important;padding-bottom: 15px !important;padding-left: 30px !important;}”][woodmart_title align=”left” size=”small” title=”Gasketed PHE Inquiry Forms” woodmart_css_id=”63067c0c84e57″ responsive_spacing=”eyJwYXJhbV90eXBlIjoid29vZG1hcnRfcmVzcG9uc2l2ZV9zcGFjaW5nIiwic2VsZWN0b3JfaWQiOiI2MzA2N2MwYzg0ZTU3Iiwic2hvcnRjb2RlIjoid29vZG1hcnRfdGl0bGUiLCJkYXRhIjp7InRhYmxldCI6e30sIm1vYmlsZSI6e319fQ==”][vc_column_text css=”.vc_custom_1645860345843{margin-bottom: 0px !important;}” woodmart_inline=”no” text_larger=”no”]

Plate Pack

The plate pack is the heat transfer surface consisting of a series of formed metal plates compressed between the fix frame and movable frame.

• Corner ports allow passage of the hot and cold liquids between the plates

• Molded gaskets along the plate edge and around the ports prevent leakage and fluid intermixing

• Wide range of corrugation patterns and plate thicknesses for optimizing thermal length and efficiency

• Combining plates that have a variety of corrugation angles induces greater turbulence at lower flow rates and creates a high film coefficient

• Single and multiple – pass configurations selected based on process requirements. Multi-fluid configurations are also available

• In-phase corrugation patterns available for applications with fluids containing particulates

• Materials of construction are selected based on compatibility with fluids and temperature

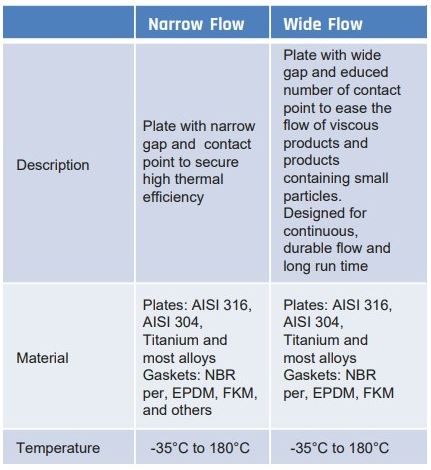

Narrow Flow

For processing low-viscosity media. Designed for high thermal efficiency with a very close tempera ture approch.

Wide Flow

For medium or high viscosity media. Designed for continuous process and long run time

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=”” woodmart_inline=”no” text_larger=”no”]

Plate Design Types

Hygienic Frames: Extendable frames to meet stringent requirements

Frame: A rigid structure that holds the plate pack in alignment and maintains gasket compression, providing a proper seal.

Frame Components

- Fix frame and movable frame

- Top and Bottom support column

- Tie Bars

- End Support

Industrial Frames: Wide range of extendable frames for meeting various quality needs.

Gasket

Molded gaskets in the through-port area of the plate provide a double seal between the fluid streams and prevent intermixing. Gasketed Plate Heat Exchanger

Gaskets in the groove around the perimeter of the plate seal the fluid between the plates.

Available in a variety of material compounds depending on temperature and compatibility with fluids.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=”” woodmart_inline=”no” text_larger=”no”]

Features of Gasket Used in Plate Heat Exchanger:

- Standard gasket.

- Protection groove of gasket: Gasket groove prevent the pads from being squeezed out and prolong its service time.

- Rubber gasket adopts latch-locked design, with observation holes for leakage.

- The fixed and seal functions are separate, even if there are some problems in fixed functions, its seal function can still work

Brazed plate heat exchanger material

The BPHE (Brazed Plate Heat Exchanger) main components are stainless corrugated plates and copper sheet, the stainless steel plates are brazed together by brazing material (Copper or Nickel) in Vacuum furnace. Copper brazed heat exchanger can be used for numerous of applications. However, for food or applications involving aggressive fluids, Nickel brazed units are recommended.[/vc_column_text][vc_single_image image=”7654″ img_size=”250×250″ alignment=”center” css=”” parallax_scroll=”no” woodmart_inline=”no”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=”” woodmart_inline=”no” text_larger=”no”]

Industrial Typical Applications of Gasketed Plate Heat Exchanger

Gasketed Plate Heat Exchanger provides advanced heat transfer solutions for cooling, heating, condensing and evaporation of process fluids and utility applications -design to solve heat transfer process Challenges in a vast array of industries…[/vc_column_text][vc_single_image image=”5064″ img_size=”full” alignment=”center” woodmart_inline=”no” parallax_scroll=”no”][vc_single_image image=”5065″ img_size=”full” alignment=”center” woodmart_inline=”no” parallax_scroll=”no”][/vc_column][/vc_row]