CIP Systems

CIP Systems

CIP Systems is a mobile cleaning system for sanitation and sterilization of containers and pipelines.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

CIP Systems Application

TMXFLOW CIP 101 is a mobile cleaning system for sanitation and sterilization of containers and pipelines. Optimum cleaning equipment for breweries and other food production facilities.

Clean-In-Place CIP Systems allows it to prepare and circulate alkali detergents and acids using a pump using hoses and sanitary showers, which are used by sanitizing. The device consists of a stainless steel chamber with a nominal volume of 300 liters, a centrifugal pump, electrical control panel, manual valves and all their pipes.

It provides a temperature of 0-80 °C. This type of CIP stands should be designed for the cleaning and sanitation of fermentation tanks, and storage tanks, all pipelines of 0 to 4000 liter water tanks, and other vehicle or food contact equipment.

Operation

Less preparatory work: Sanitizing solutions are always prepared in the CIP containers and they are available in the desired dilution for several cleaning and sanitizing cycles. Their preparation before each cleaning and sanitizing cycle is not needed.

Increasing work safety: Limiting the frequency of manipulation with sanitizing solutions reduces the likelihood of burns the operator when handling concentrated acids and alkalis.

Saving of time and energy: Continuous heating of cleaning and sanitizing solution during the cleaning and sanitizing cycles and keeping them at a prescribed temperature increase considerably the efficiency of cleaning and sanitation, resulting in time saving operation of the equipment and saving of electricity consumption. All cleaning process, pump operations, heating of sanitizing solutions and water, they all take significantly less time, require less human work and electric energy.

High efficiency of cleaning and sanitation: Compared with the cleaning and sanitizing of the food processing equipment by simple circulation pump there is still the same temperature of the sanitizing solutions during all time of the CIP cycle, if our CIP unit is used for this operation. Cleaning and sanitation with hot water and disinfectant solutions is definitely more effective than the same procedure with cold solutions, and therefore containers and equipment are perfectly clean after disinfection and washing cycles and are also free of organic and other impurities, which is desirable not only in the brewing industry but also in any other beverage or food production process. This is a prerequisite for compliance with legal hygiene requirements.

Simple and efficient neutralization of acid and alkaline solutions after use: Neutralizing vessel (part of the CIP station) allows easy, safely and completely neutralize the used acid and alkaline sanitizing solution before pouring into the channel. It fully meets the requirements of laws to protect the environment and prevents damage to sewerage systems and other building components. Furthermore, this increases the safety when handling used washing and sanitization solution.

User Benefits

- Pre-rinsing – rinsing of the production equipment using cold or hot water.

- Cleaning – cleaning of the production equipment using circulated hot water.

- Rinsing – thorough rinsing of the production equipment using cold or hot water.

- Chemical disinfection (sanitation) – washing of technology using alkaline and then acid sanitizing solution at the desired concentration.

- Rinsing – thorough rinsing of the production equipment using cold or hot water.

- Neutralization – is performed after the finish of several cleaning and sanitizing cycles – mixing alkaline and then acidic sanitizing solution to achieve neutral pH of the solution and their discharge to the channel.

Downloads & Documents

CIP Systems Inquiry Form

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.

Technical Specitifications

Design and Features

CIP Systems includes the following elements:

- 1 insulated 300L tank for preparing the cleaning solution.

- Electrical resistance heating with temperature regulation fitted in the tank.e

- Constant level in the tank using a pressure switch and a control panel display.

- Collectors with manually operated butterfly valves.

- Base frame with wheels.e

- Stainless steel electric panel.

Materials:

Tank AISI 316L (1.4404)

Piping in contact with the product AISI 316L (1.4404)

Base frame and other steel parts AISI 304 (1.4301)

Pump SC28 4KW

Mechanical seal:

Rotary part Ceramic (Cer)

Stationary part Carbon (C)

Gaskets EPDM

Electrical resistance 2×7,5 KW

Tank insulation Mineral wool

Operating limits:

Tanks requiring cleaning up to 3.000 L

Cleaning flow rate 10.000 L/h

Cleaning pressure 3 bar

Options

300L tank and CIP Systems return pump for water recovery: Recommended for water saving and recovery in rinsing after sterilization

Dosage pump: It sets the CIP solutions to enter the system.

Conductivity Meter: It measures the cleanliness of the system in the return line.

Neutralization Container: The neutralization container provides easy and safe neutralization of the used acid and alkali disinfectant solution before pouring it into the channel.

Self-cleaning kit: Spray balls and necessary stainless piping are included in this kit. The kit is for the CIP system to clean itself.

Hose cleaning kit: Various valves and the necessary stainless pipe line are included in this kit. This kit is for cleaning the pipe or hose line in the system.

Sight Glass

Flow Rate Meter

Tank insulation and jackets

Spray Ball

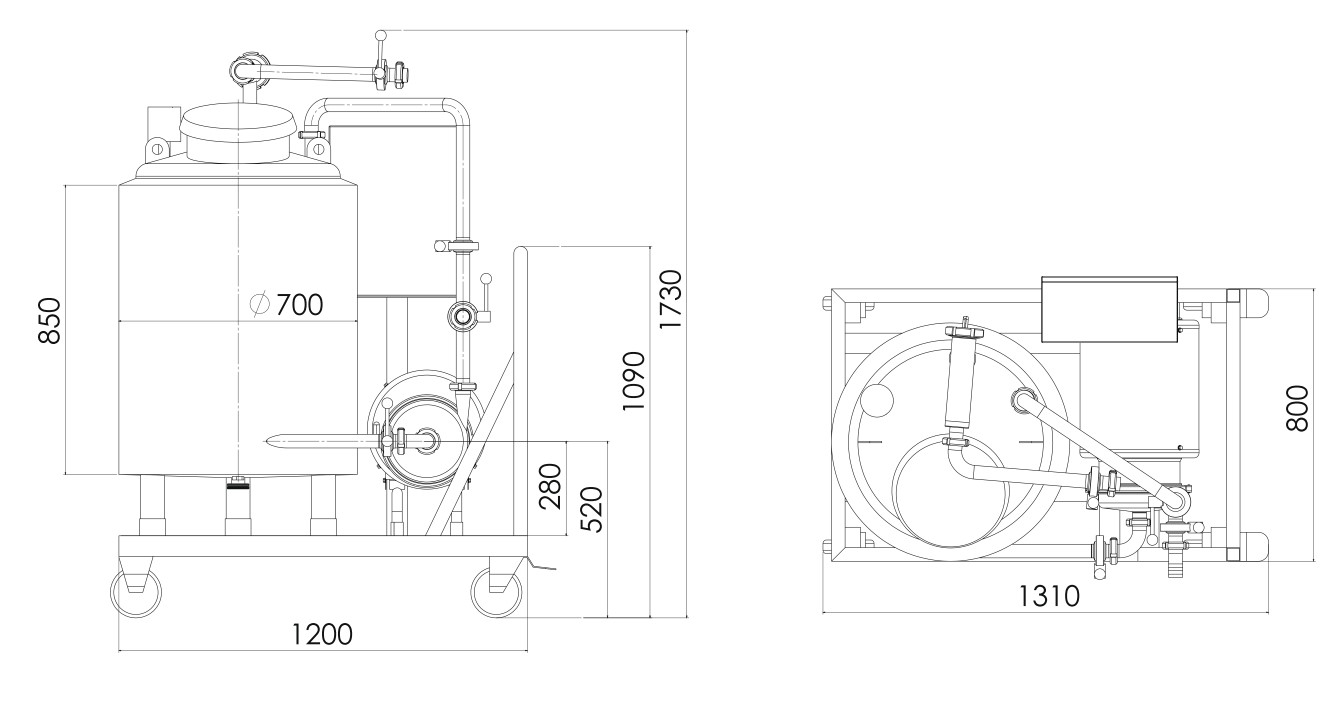

Dimensions: manual CIP systems with 1 tank