Blog

What Are SLA Lobe Pumps? A Complete Guide for Industrial Fluid Handling

SLA Lobe Pumps offer a smart solution for energy-efficient, hygienic, and eco-friendly fluid transfer in modern industries.

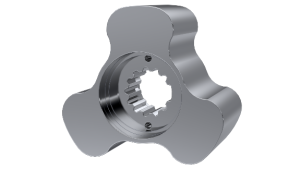

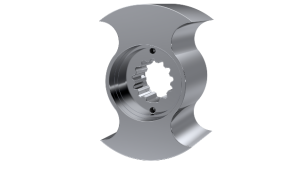

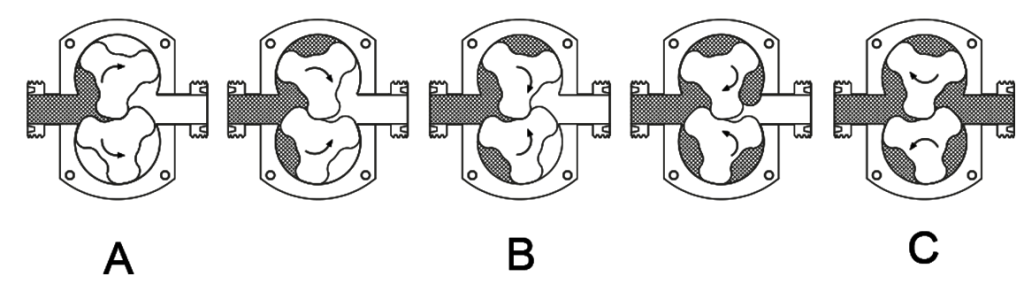

How Do SLA Lobe Pumps Work?

SLA lobe pumps operate using a rotary lobe mechanism where two synchronized lobes rotate inside a casing. As the lobes turn, they create expanding cavities on the suction side, drawing fluid in. The fluid is then trapped between the lobes and casing and pushed out through the discharge side.

- Non-contacting lobes (no metal-to-metal wear)

- Low pulsation flow

- Gentle handling of sensitive fluids

- Bidirectional flow (reversible operation)

Key Features of SLA Lobe Pumps

1. Hygienic & Clean-In-Place (CIP) Design

Made from 316L stainless steel, these pumps support CIP and SIP systems, making them ideal for food and pharmaceutical applications.

2. Wide Range of Viscosities

- Low-viscosity fluids (e.g., juices, milk)

- High-viscosity substances (e.g., honey, creams, syrups)Fluid

- s with delicate solids (e.g., fruit pieces, curds)

3. Energy Efficient

Designed with optimized flow paths and precision tolerances, SLA Lobe Pumps reduce energy consumption and carbon footprint.

4. Gentle, Low Shear Flow

The smooth, non-turbulent flow preserves product texture and molecular integrity — ideal for cosmetics, yogurt cultures, and bioactives.

5. Durability & Easy Maintenance

• Front-loading seals

• Modular, easy-to-disassemble design

• No need to disconnect pipework

Typical Applications of SLA Lobe Pumps

- Food & Beverage: Milk, yogurt, chocolate, sauces, wine

- Dairy: Cheese curd, cream, whey

- Pharmaceutical: Syrups, ointments, gels, vaccines

- Cosmetics: Shampoo, lotions, toothpaste

- Chemical: Paints, resins, adhesives, solvents

SLA Lobe Pumps vs Traditional Pumps

| FEATURE | GEAR PUMP | LOBE PUMP |

| PRESSURE RESİSTANCE | High | Medium |

| VİSCOSİTY COMPATİBİLİTY | Medium-High | Very High (e.g honey, cream, etc.) |

| PARTİCLE HANDLİNG | Poor | Good |

| HYGİENİC DESİGN | Generally No | Yes (CIP/SIP compatible) |

| PRODUCT SENSİTİVİTY | Low | High (gentle transfer) |

| EASE OF CLEANİNG | Difficult | Easy (especially with Tri-Clamp) |

Why “Economic” in SLA Lobe Pumps?

- Eco-Friendly: Lower energy usage, less waste

- Economical: Lower operational costs

- Efficient: Reliable flow under demanding conditions

Conclusion: Are SLA Lobe Pumps Right for You?

Discover how SLA Lobe Pumps can transform your fluid handling process with hygienic, efficient, and sustainable performance.