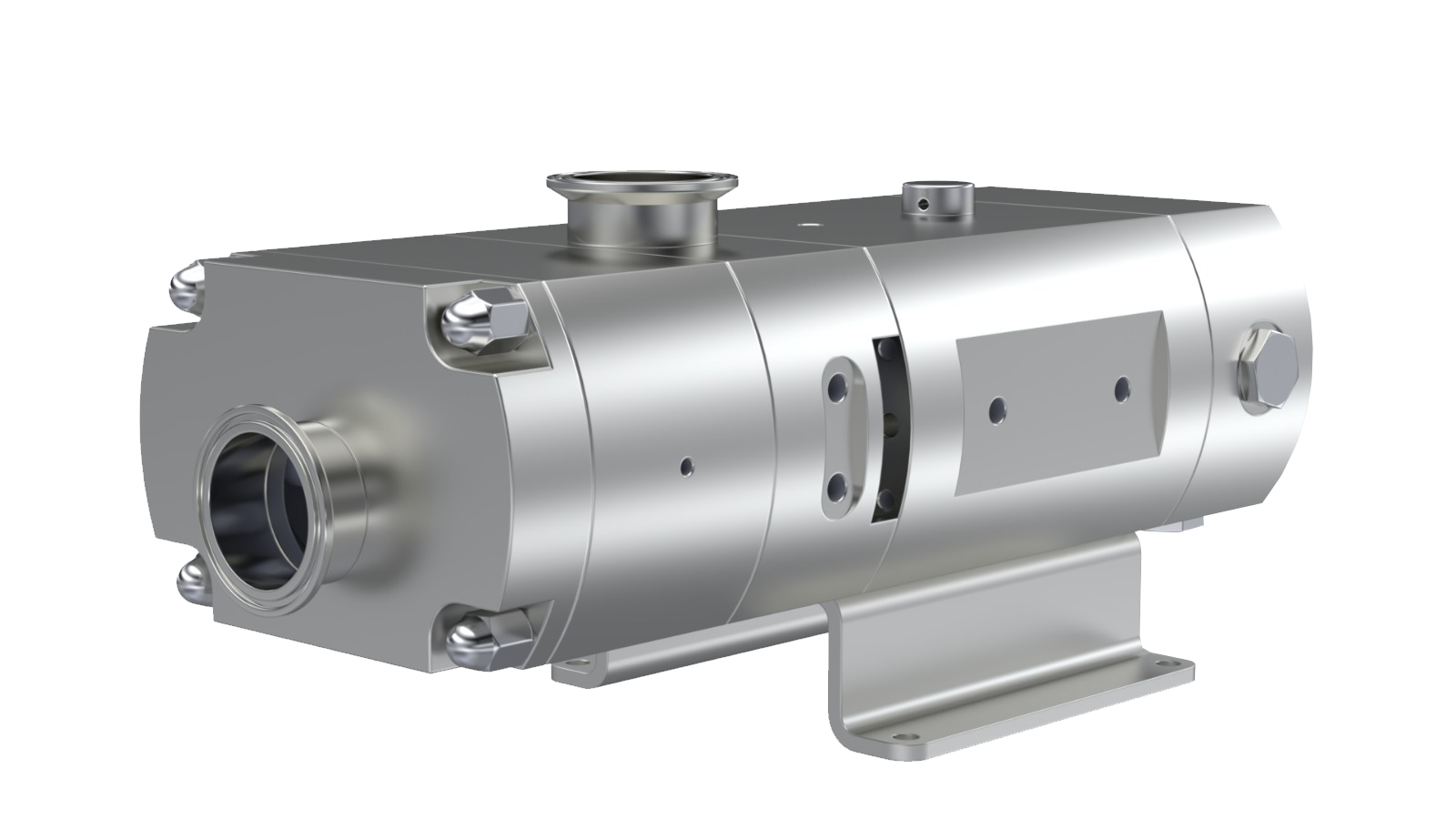

Twin Screw Pumps

Twin Screw Pump for great performance

Twin screw pump, with a hygienic design, suitable for use in the food, dairy, beverage and cosmetic industries.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Application

Twin screw pump, with a hygienic design, suitable for use in the food, dairy, beverage and cosmetic industries.

The flow is uniform and in an axial direction, so there are no changes in the volume or physical properties of the product. Therefore, it is an ideal pump for handling shear-sensitive fluids.

It has a high suction lift capability with very low NPSH values.It is capable of pumping liquids with high viscosity, but also with low viscosity, so it can be used as a CIP-supply pump. The design ensures full cleanability and drainability.

Operation

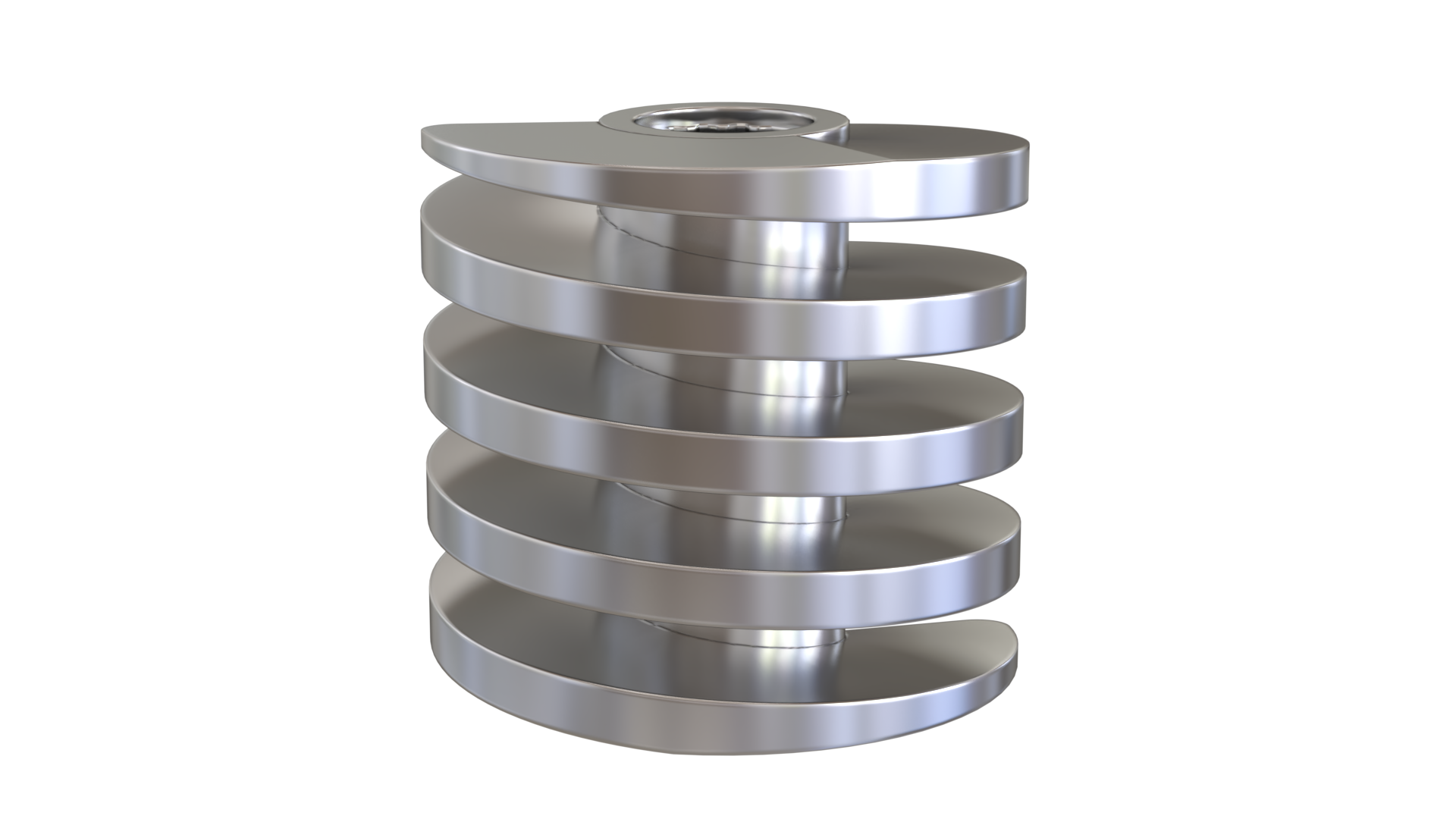

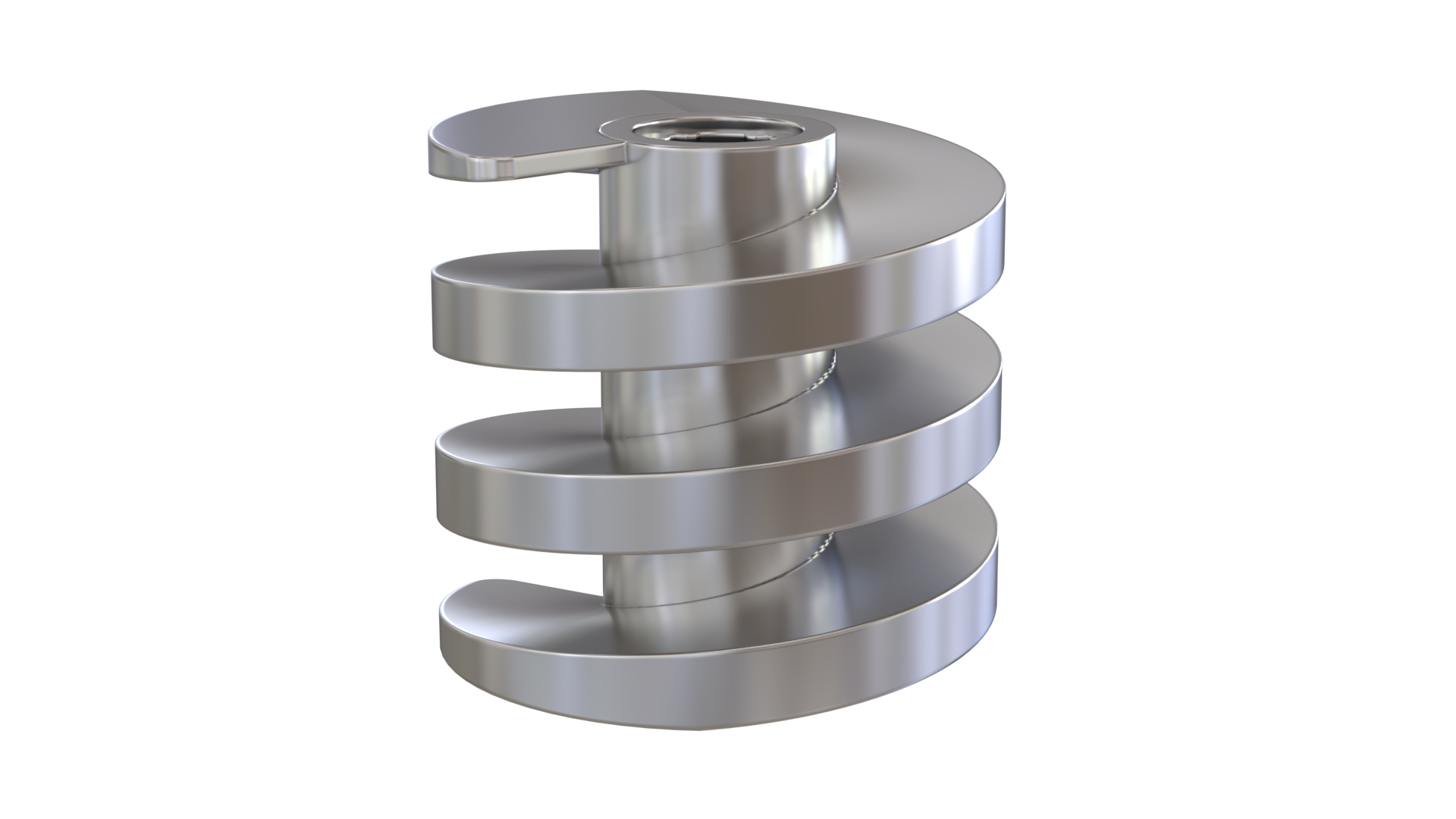

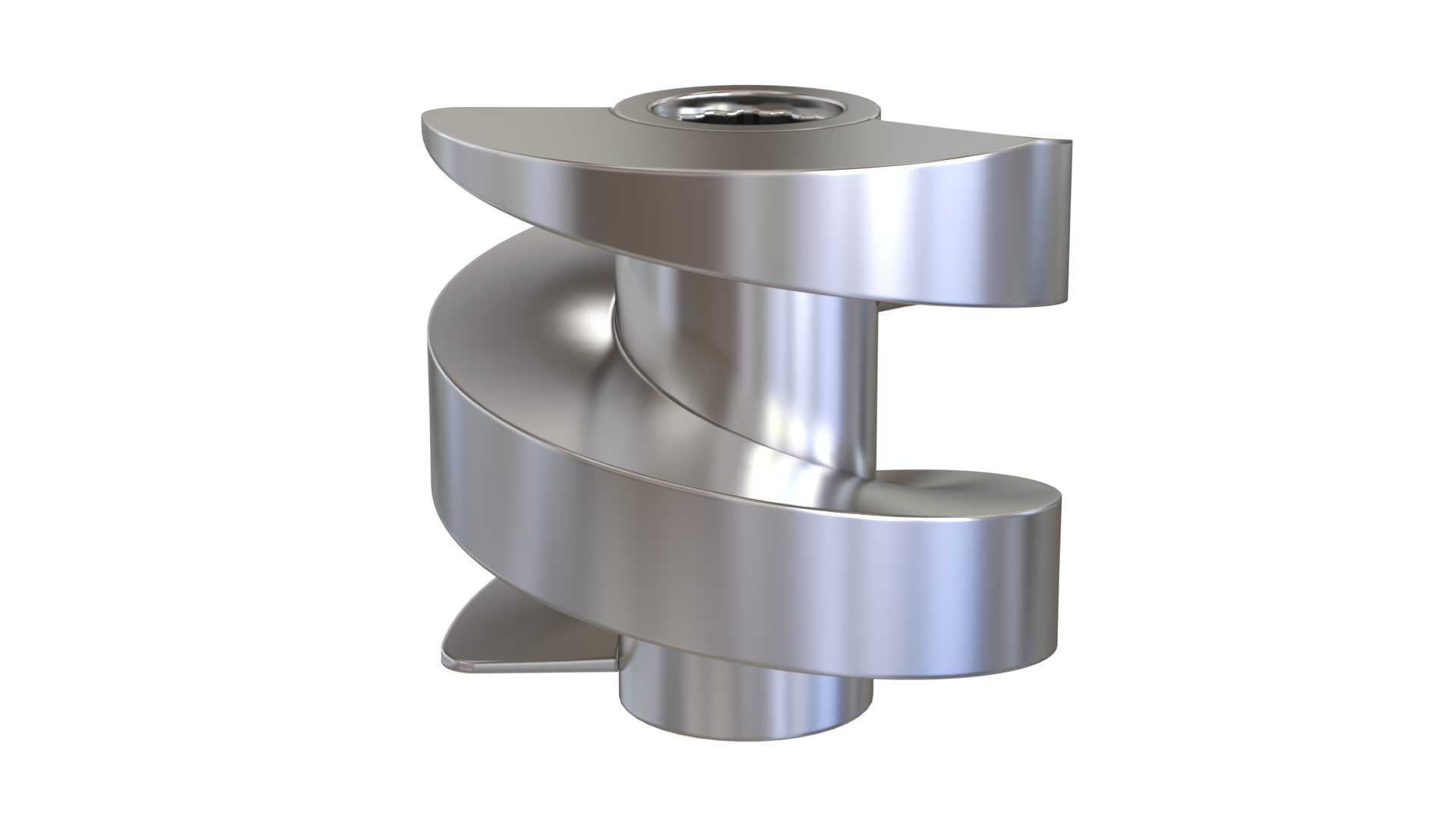

Twin screw pump is a positive displacement pump what means that the pump is transferring a certain volume of product in accordance with the speed and pitch of the screws. While turning, the two screws are forming closed chambers that are moving in an axial direction.

This movement creates a vacuum at the inlet side and pressure at the outlet. Due to this double chamber technic, there is an almost pulsation free working with high and low viscosity products.

Technical Specitifications

Materials

Pump casing…………………….AISI 316 diffusion hardened

Screws, front cover, seal housing….AISI 316 diffusion hardened

Inside surface finish………..Ra ≤ 0.8

Gear box……………………………Stainless steel / Cast Steel

Base plate………………………….Stainless steel

Coupling guard…………………Stainless steel

Product wetted elastomers..EPDM

Other elastomers………………FPM

Shaft seal…………………………..Single / Double

Rotary seal face………………..Silicon Carbide / Tungsten

Stationary seal face………….Silicon Carbide / Tungsten

Operating Limits

Maximum flow…………110m3/h

Max working pressure….20 bar

Temperature range…….-40C to 150C

Max CIP temperature……150oC

Max Speed…………….3500rpm / 50hz

Max Speed…………….3500rpm / 60hz

User Benefits

- 100% CIP running at high speeds

- Single and double mechanical seal options

- Even when running at high pressures, there is no rotor/rotor/body contact

- Speed up to 3,500 rpm

- Ideal for abrasive products

- Gentle handling of cut-sensitive products

- Totally drainable

- Bidirectional: It is possible to recover the product from the line due to being

- Ideal for products with high air or gas content

- Perfect for vacuum applications with high and low viscosity products

Information

Twin Screw pumps are designed for precision, abrasive, high and low viscosity use.

Twin Screw pumps are designed for precision, abrasive, high and low viscosity use.

These pumps are built on a robust and reliable platform that meets stringent hygiene standards.

It can perform both product transfer and CIP transactions.

Low vibration properties and excellent solids handling increase product quality by reducing the risk of product damage.

Maintenance has been simplified and uptime has been increased.

Downloads & Documents

Twin Screw Pump Inquiry Form

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.

What Are Twin Screw Pumps?

Twin Screw Pumps are positive displacement pumps that use two intermeshing screws to move fluid through thepump housing. These screws rotate in opposite directions, creating a continuous, non-pulsating flow. They are known for handling a wide range of viscosities, sensitive liquids, and even multiphase fluids with minimal shear and turbulence.

Key Features:

Self-priming

Self-priming- Can handle high viscosity and multiphase fluids

- Low pulsation and smooth flow

- High efficiency in both high and low-pressure applications

- Can operate dry for short periods

- Easy maintenance due to their simple design

Industries & Applications

- Oil & Gas

- Crude oil transfer

- Pipeline boosting

- Multiphasic fluid handling (oil, gas, and water mixtures)

- Refineries & petrochemical plants

- Food & Beverage

- Dairy products (milk, cream, yogurt)

- Chocolate, syrups, and sauces

- Brewery applications (beer, wort, yeast handling)

Hygienic processing with CIP (Clean-in-Place) compatibility

- Pharmaceutical & Cosmetics

- Handling creams, gels, and lotions

- Hygienic and sterile fluid transfer

- Biopharmaceutical liquid processing

- Chemical & Petrochemical

- Corrosive and viscous chemical transfer

- Solvents, resins, and adhesives pumping

- Polymer and latex processing

- Marine & Shipbuilding

- Fuel and lubrication oil transfer

- Ballast and bilge pumping

- Cargo handling (tankers, ships)

- Power Generation

- Fuel oil transfer for turbines and generators

- Cooling and lubrication systems

- Pulp & Paper Industry

- Coating and starch applications

- Black liquor and chemical handling

- Wastewater Treatment

- Sludge handling

- Industrial wastewater processing

Why Choose Twin Screw Pumps?

- Versatility: Works with various liquids (low to high viscosity, corrosive, or shear-sensitive)

- Efficiency: Handles multiple phases and ensures continuous flow

- Reliability: Long service life with minimal maintenance