Lobe Pumps

Lobe Pumps for great performance

Lobe Pumps range has been developed for general applications within the Dairy, Beverage, Food, Chemical and Personal Care industries.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Lobe Pumps Application

Lobe Pumps range of rotary lobe pumps combines cost effective simplicity and easy maintenance with TMX quality and reliability.

Lobe Pumps range of rotary lobe pumps combines cost effective simplicity and easy maintenance with TMX quality and reliability.

Lobe Pumps range has been developed for general applications within the Dairy, Beverage, Food, chemical and personal care industries.

Fully with CIP cleanable. This pump is also perfect for handling any liquid with low or high viscosity.

When it comes to filtration and bottling applications. Products containing brittle solids such as curd.

Thanks to specially designed lobes, it can be pumped without damage. Easy inspection or replacement without the need for pipework disassembly.

Lobe pump is a bare shaft rotary lobe pump. It is made of a stainless steel.

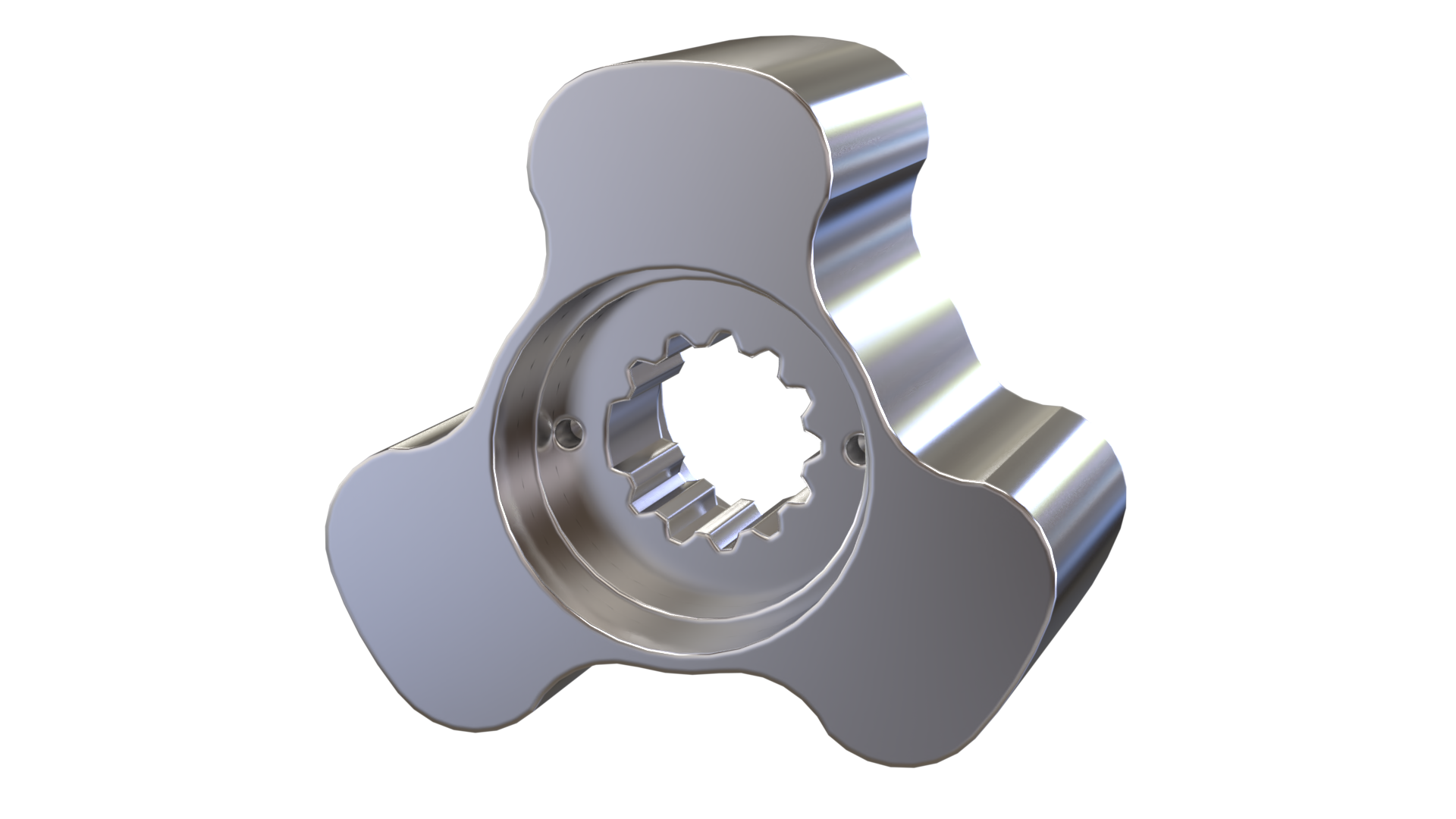

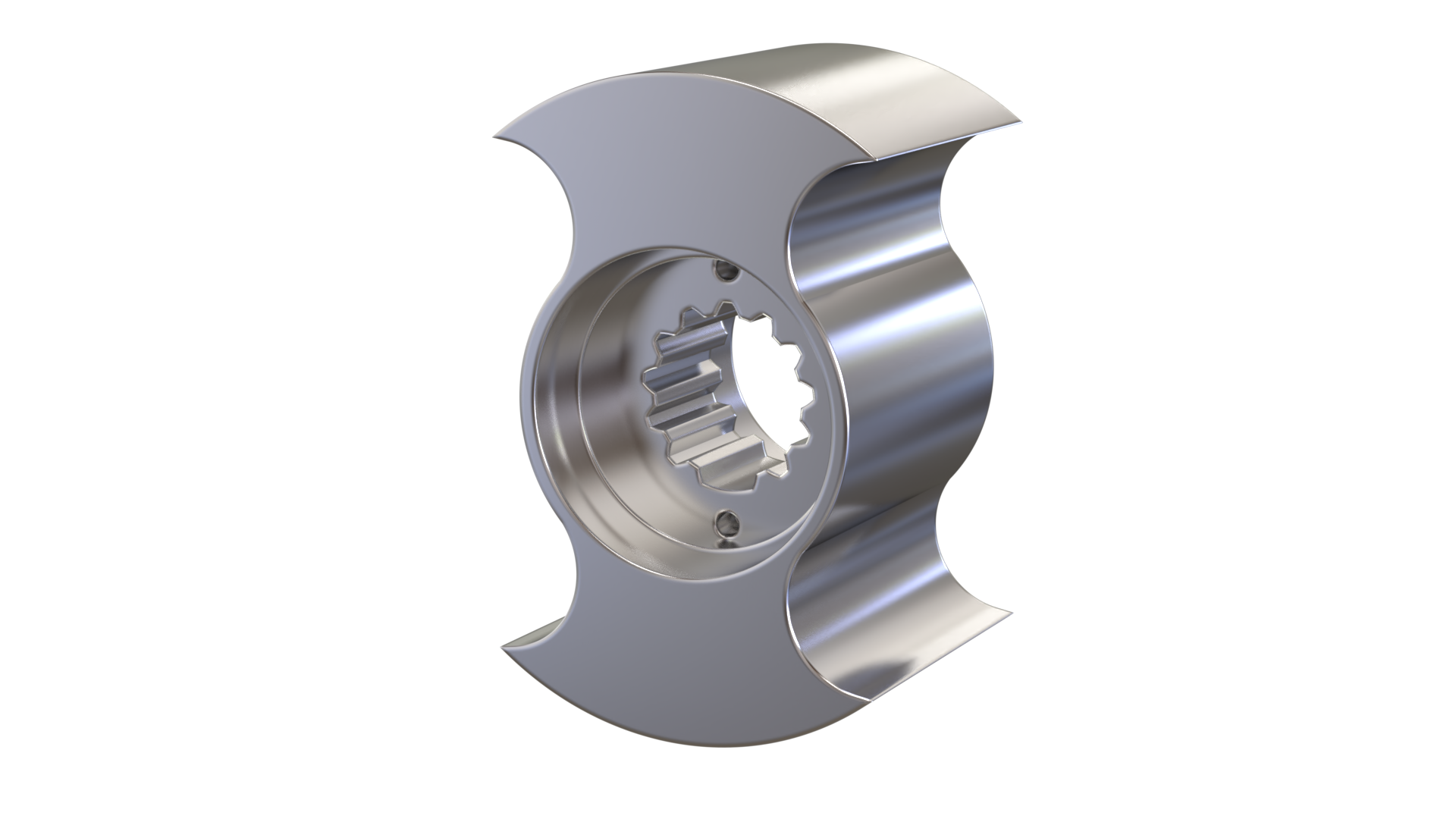

Pump casing and cover, and two-lobe rotors with sanitary attachment.

Rotary lobe pumps is provided with an internal mechanical seal approved EHEDG. The seal is balanced and has a hygienic design. When required, other materials can be used.

Lobe Pumps range is compact, efficient and capable of flow rates up to 122m3/h and pressures up to 12 bar.

User Benefits

- High efficiency

- Low energy consumption

- Compact size

- Smooth flow

- Reversible operation

- Low shear pumping

- Minimal pumped media agitation

- Easy maintenance

- Hygienic design

Operation

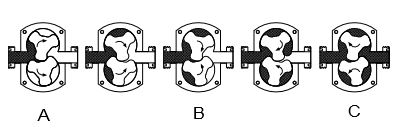

The positive displacement of the Series Lobe pump is provided by non-contacting, contra-rotating two or tri-lobe rotors within a fully swept pump chamber.

Materials

Pump Head Housing: AISI 316L

Gaskets: EPDM or FPM

Gear Box: GG25

Shafts: Duplex Stainless Steel

Shaft Seal: Single,Double Mechanical Seal

Surface Finish: Ra<0,8 μm

Connections: DIN 11851, SMS, ISO, Clamp

Base Plate: Stainless Steel

Coupling Guard: Stainless Steel

Operating Limits

Maximum flow: 122 m3/h

Maximum differential pressure: 12 bar

Maximum working pressure: 12 bar

Temperature range (EPDM): -10 °C to +120 °C

Temperature CIP, max. 30 min: +140 °C

Maximum speed: 950 rpm

Downloads & Documents

Lobe Pumps Inquiry Forms

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.

What is a Lobe Pump?

Lobe pumps are mechanical devices used to transport liquids and viscous substances precisely and reliably. These pumps, in which two gear-shaped rotors (lobels) move close to each other, are ideal for viscous and shear-sensitive liquids. Lobe pumps operate at low speeds, preserving the structure of the liquid, thus ensuring that the liquid is transported without damaging its original properties.

Industrial Applications

Lobe pumps are widely used in a wide range of industries. These include:

- Dairy and Beverage Industry: Lobe pumps are widely used in the transportation of sensitive food substances such as milk and dairy products. They are also preferred in the beverage sector for the safe pumping of fruit juice, soda and soft drinks.

Food Industry: Lobe pumps play an important role in the transportation of products such as high-viscosity food substances, syrups, chocolate and honey. Lobe pumps ensure that the product is transported without damaging its taste, color and texture.

Food Industry: Lobe pumps play an important role in the transportation of products such as high-viscosity food substances, syrups, chocolate and honey. Lobe pumps ensure that the product is transported without damaging its taste, color and texture.- Chemical Industry: Lobe pumps are also widely used in the transportation of chemical substances. They are ideal for chemical liquids that do not require cutting and difficult liquids such as acidic and alkaline substances.

- Personal Care Industry: Lobe pumps protect the quality and efficiency of products such as shampoo, soap, lotion and other cosmetics. The transportation of sensitive components and viscous products without damage is very important in the personal care sector.

The advantages of lobe pumps

The advantages of lobe pumps are their reliability, long life and energy efficiency. These pumps are an excellent choice to meet the precision and efficiency requirements in industrial processes.