SB-100 Horizontal Blender

SB-100 Horizontal Blenders for great performance

SB-100 Horizontal Blender is used to dissolve solid / powder products in to a liquid, recirculated in a tank.

Dairy

Cosmetic

Food

Pharmaceutical

Brewery

Syrups

Horizontal Blender Application

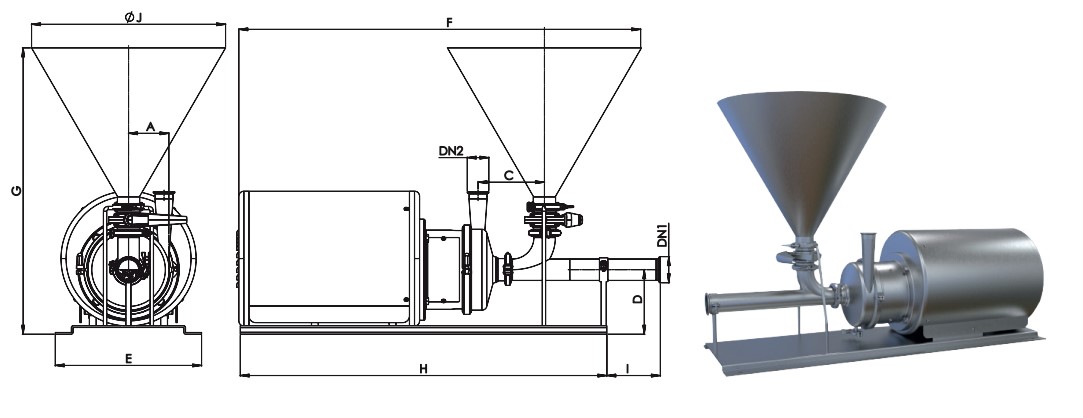

SB-100 Blender is used to dissolve solid / powder products in to a liquid, recirculated in a tank. The blender is limited to the suction of small amount of solids as it has no table for bags and the hopper is smaller than that of the table blender.

Horizontal Blender Working Principle

SB-100 Horizontal Blender is a compact unit, it consists of a centrifugal pump witha venturi system on the suction side and a hopper with a butterfly valve above the venturi to add solid / powder products to the pumped liquid. The venturi system and the suction of the pump create a negative pressure at the base of the hopper. To achieve the best possible dissolution, it is recommended to recirculate the product.

Materials

- Parts in contact with the product: AISI 316L

- Other metal parts: AISI 304

- Gaskets: EPDM

- Mechanical seal: SiC/C/EPDM

- Internal Bright Polish Ra : ≤0,8 m

- External: Matt

Design and Features

- Easy assembly and cleaning

- Hygienic design.

- Single Mechanical seal

- ISO 2852 Clamp connections for easy assembly /disassembly.

- Cleaning and disinfection without disassemby

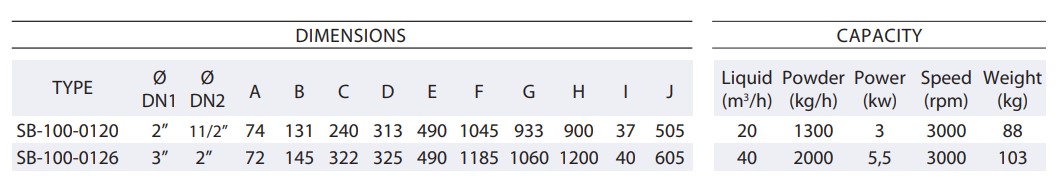

SB-100 Horizontal Blenders Dimensions and Capacity

Options

- Gaskets FPM or PTFE

- Connections DIN, SM

- Vibrator for hopper.

- Pneumatically actuated valve + low level sensor for solids.

- Solids upper level sensor

Downloads & Documents

SB-100 Horizontal Blender Inquiry Form

CONTACT INFORMATION

Do you have questions about how our products can help you? Send us an email and we’ll get in touch as soon as possible.

Horizontal Blenders

Blenders, essential equipment in various industries, are cutting-edge machines designed to streamline and enhance the blending and mixing processes of diverse materials. These blenders are meticulously engineered to accommodate the intricate requirements of modern manufacturing, ensuring optimal consistency, homogeneity, and quality of end products.

Characterized by their horizontal orientation, these blenders boast a unique design that enables efficient and thorough mixing of a wide range of raw materials, ingredients, or components. Their versatility makes them an indispensable asset across industries such as food and beverage, pharmaceuticals, chemicals, cosmetics, and more.

Equipped with state-of-the-art features, horizontal blenders offer precision and flexibility in their operation. They often incorporate advanced control systems that allow operators to fine-tune mixing parameters such as rotation speed, blending time, and intensity, resulting in tailored outcomes that match the specific needs of each production batch. This level of control not only improves product consistency but also minimizes material waste and maximizes overall efficiency.

One of the key advantages of horizontal blenders is their ability to perform gentle blending without causing excessive shear or degradation of sensitive materials. This attribute is particularly critical in industries such as pharmaceuticals and food, where preserving the integrity of ingredients is paramount to the final product’s efficacy and quality.