Posts by gozde

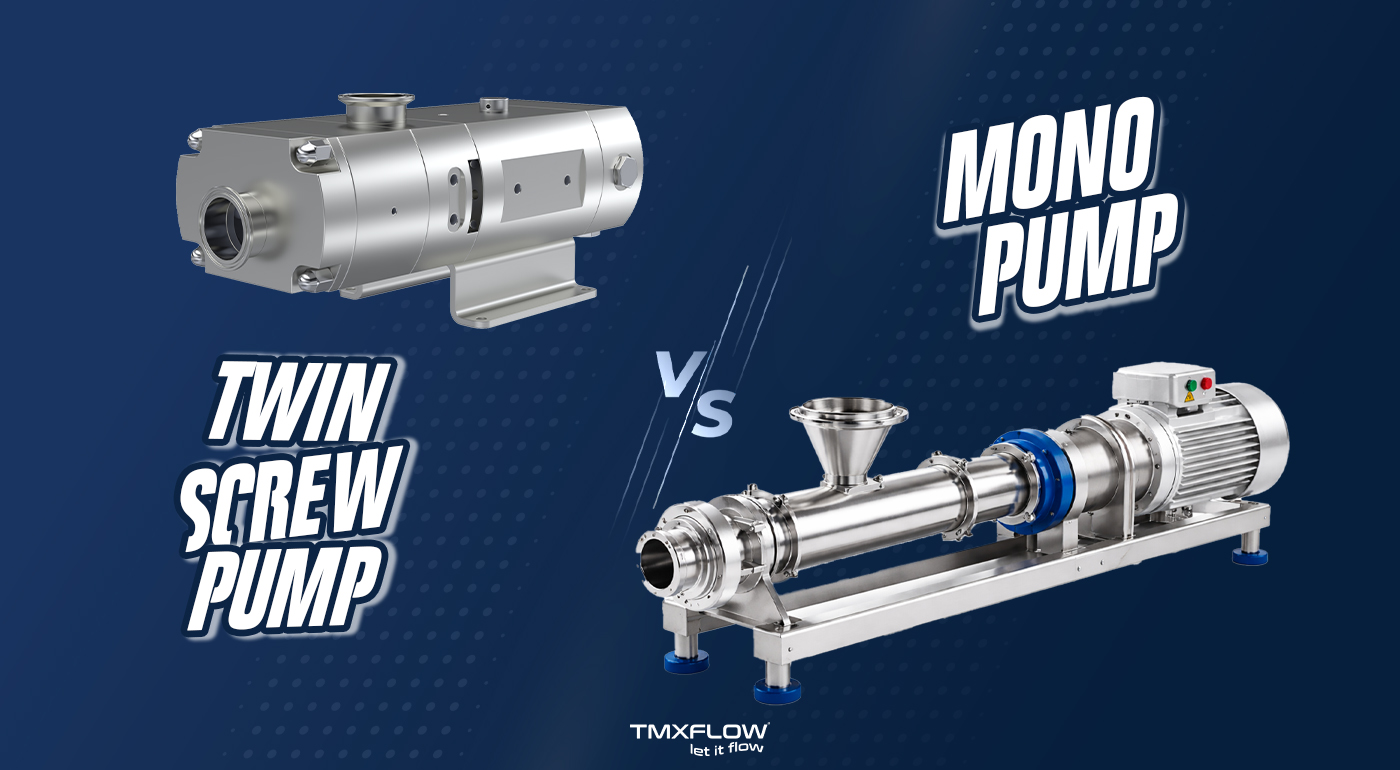

The Importance of the Right Pump: Twin Screw or Progressive Cavity Pump?

THE IMPORTANCE OF THE RIGHT PUMP:

Twin Screw or Progressive Cavity pump?

Imagine you are a syrup producer for the food industry.

Your company is growing, and a new process is being designed to produce high-viscosity syrup, typically above 5,000 cP, with a target capacity of several thousand liters per hour. The product is thick, sticky, and sensitive, and the process must run reliably every day.

At the same time, strict hygienic requirements apply:

- Stable and repeatable flow

- Efficient CIP cleaning between batches

- Minimal maintenance and downtime

- Compliance with food industry standards

At first glance, both pump technologies seem to fit the application.

Both technologies handle viscosities above 5,000 cP

From a hydraulic point of view, both progressive cavity and twin screw pumps are capable of handling syrup above 5,000 cP. Flow stability, pressure capability, and gentle product handling can be achieved with either technology.

The difference becomes clearer when the pump is evaluated as part of the entire process, not only by viscosity or capacity.

Progressive Cavity (Monopump): practical limitations

Progressive cavity pumps perform well with viscous products, but in food applications with frequent cleaning and temperature variations, some limitations may appear:

- The elastomer stator is a wear component over time

- Rubber materials such as EPDM or NBR limit operation at higher temperatures

- Product retention inside the cavities can reduce CIP efficiency, especially with sticky syrups

- Speed is limited during CIP, reducing cleaning flexibility

- Stator wear directly affects performance and maintenance intervals

These factors can increase maintenance dependency and cleaning time in continuous production.

Twin Screw technology: same viscosity range, more process flexibility

Twin screw pumps also operate well above 5,000 cP, but with a design that offers additional advantages for hygienic processes:

- Product contact parts manufactured entirely in AISI 316L stainless steel

- No elastomers in the product path, allowing higher operating temperatures

- Stable flow across a wide viscosity range

- Excellent CIP performance with minimal product hold-up

- Ability to run at higher speeds during CIP, similar to a centrifugal pump

- Flexible drive options, including gearbox or direct motor coupling

- Longer service intervals and reduced maintenance sensitivity

From TMX’s experience in hygienic processes, twin screw pumps for syrup and sugar applications can be equipped with tungsten mechanical seals and double mechanical seal arrangements, supporting abrasive products, temperature variations, and intensive CIP routines. The result is not only good pumping performance, but a more robust and adaptable process.

Why this matters in real production

Above 5,000 cP, both technologies can move syrup effectively.

The key difference lies in cleaning efficiency, temperature flexibility, sealing reliability, maintenance behavior, and long-term process stability.

Final thought

Selecting a pump is not only about viscosity.

It is about how the pump supports the entire process over time.

In demanding syrup applications, twin screw technology often delivers added value beyond flow, supporting hygiene, flexibility, and operational reliability.

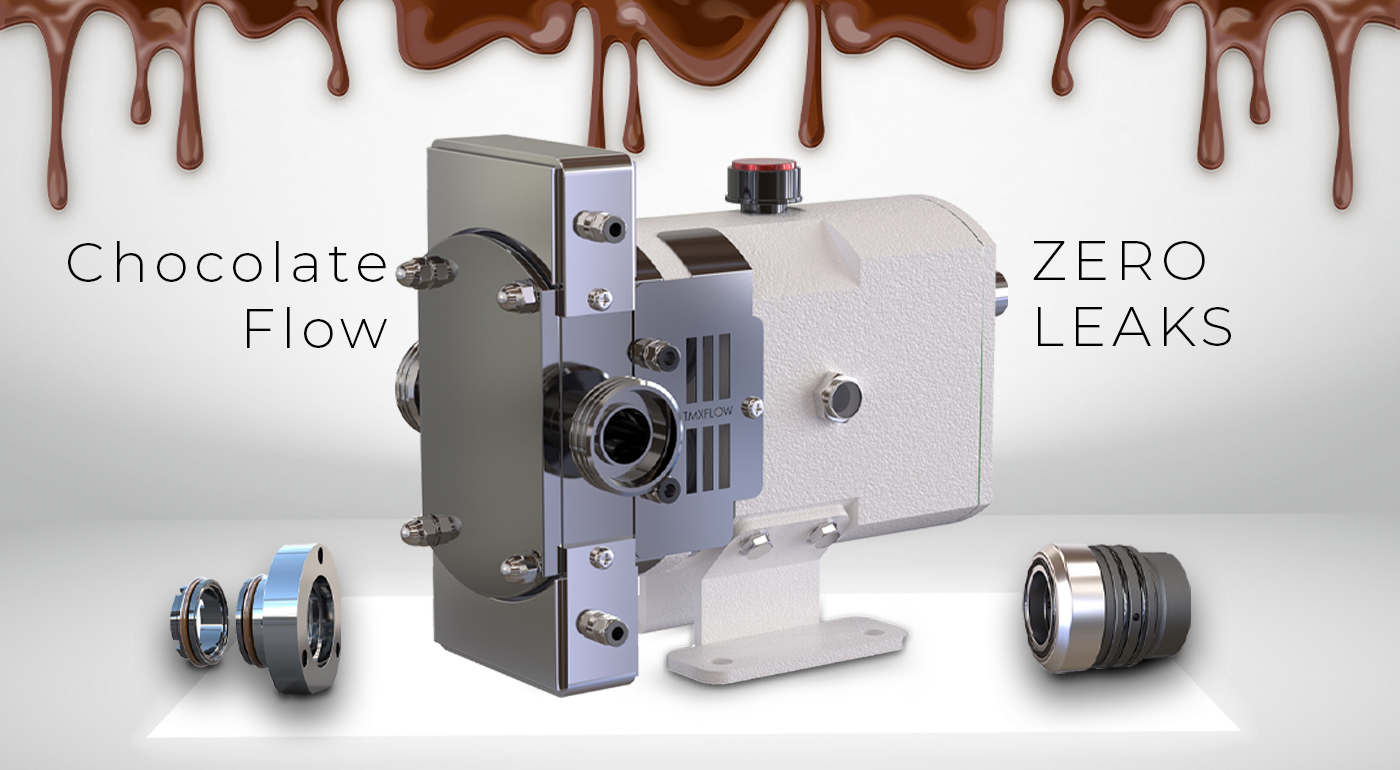

How TMX Transformed the Production Line of a Major Chocolate Factory

TMX Chocolate Factory Production Line

Case Study: Eliminating Leaks and Boosting Performance with TMXFLOW Chocolate Pumps

Chocolate production demands precision, temperature control, and reliable equipment. When a major factory in the sector began facing recurring issues such as leakage, efficiency loss, and unstable chocolate flow, TMX was called in to conduct a full assessment of the operation.

After a detailed technical analysis, our team identified the key critical points in the production line — especially in areas where valves and pumps were unable to maintain continuous flow and the ideal product temperature.

We then implemented our full range of TMXFLOW chocolate pumps, designed to ensure thermal stability and maximum performance. With integrated heating jackets, we ensured smooth, homogeneous chocolate flow without crystallization or changes in viscosity.

🚀 Results Achieved

The TMXFLOW solution delivered immediate and measurable improvements:

- Zero leakage, eliminating waste and contamination

- Significant increase in production efficiency

- Improved product quality and safety

- Stable chocolate flow enabled by optimized temperature control

- A cleaner, safer, and more cost-efficient operation

Today, this factory operates at a much higher performance level — and TMX has become a benchmark in delivering complete solutions for chocolate processing.