Posts by TMXFLOW

SLA Chocolate Industry

Why Choose Lobe Pumps for the Chocolate Industry?

In the chocolate industry, pumping is not just a transfer stage — it is a critical point that directly influences the final quality. Chocolate is a highly viscous raw material, sensitive to shear, and requires strict temperature control to maintain its characteristic texture, shine, and flavor.

This is where lobe pumps stand out as one of the most recommended solutions.

Why choose lobe pumps for chocolate?

- Smooth and continuous flow

Lobe pumps ensure uniform pumping with minimal pulsation, preserving the structure of the chocolate throughout the process. - Low shear

This type of pump protects the cocoa butter crystals, maintaining creaminess and preventing unwanted changes in texture. - High capacity for elevated viscosities

Ideal for dense masses, thick fillings, and coatings, lobe pumps handle difficult-to-pump products without compromising efficiency. - Compatibility with heating systems

Often equipped with heating jackets, they prevent solidification inside the pump and maintain consistent fluidity throughout production. - Hygiene and food compliance

Designed to meet the highest hygiene standards, they are compatible with CIP/SIP processes, which are indispensable in food factories. - Versatility

Beyond pure chocolate, they allow pumping of recipes with particulates such as nuts, peanuts, or dried fruits, without damaging their integrity.

Why not opt for other pump types?

Other pumping technologies, such as centrifugal or gear pumps, show limitations in chocolate applications: excessive shear, difficulties handling high viscosities, or risks of damaging product texture. Lobe pumps, on the other hand, combine robustness, hygiene, and delicacy in handling — a crucial balance in this sector.

👉 If your factory is looking for efficiency, quality, and total preservation of chocolate properties, the lobe pump is the right choice. And here at TMXFLOW, you will find specialists ready to recommend the most suitable solution for your process.

Case Study: Maximum Efficiency in Tomato Sauce Unloading

Handling viscous products in food processing is always a challenge. Beyond preserving product quality, it is essential to maintain hygiene and avoid losses when transferring raw materials from large containers into production lines.

Recently, we received a request from a client in the food industry — a raw meatball producer working with tomato sauce and ketchup supplied in 200-liter drums. These products present viscosities ranging from approximately 500 to 10,000 cP, which makes unloading and transfer to mixing tanks complex.

The challenge

The client’s priorities were clear:

- Achieve high recovery of the product contained in each drum.

- Guarantee hygienic operation throughout the process.

- Preserve the original characteristics of the sauces, even with variations in density and consistency.

The solution

To meet these needs, we implemented a Drum Unloading System (DUS). The equipment uses a follower plate with sealing that descends into the drum and pushes the product directly to the pump inlet. This approach allowed the client to:

- Recover more than 98% of the drum’s content.

- Adapt the system to products with viscosities ranging from 1,000 to over 150,000 cP.

- Benefit from custom options such as heating, automation, CIP, ATEX compliance, and pump selection according to the specific application.

Although the solution was designed here for tomato-based sauces, the same principle can be applied to a wide range of pasty products, always combining efficiency, hygiene, and consistency.

In the video below, you can see how the unloading process works in practice and how it impacts productivity and waste reduction.

Final thoughts

This was just one example of how engineering can turn a production challenge into a clean and efficient process. If your operations also deal with viscous products, it’s worth considering how the right solution can reduce losses and improve reliability. After all, efficiency is not only about technology — it’s about making every drop count.

SKD Vertical Agitators – Compact, High-Speed Mixing for Critical Applications

Introduction: The Power of Precision Mixing in Small Tanks

In industries like food, pharmaceuticals, cosmetics, and dairy, efficient and hygienic mixing in small tanks is critical. The TMXFLOW SKD Vertical Agitator is specifically designed for powerful, high-speed agitation in vessels up to 1,500 liters. With a compact design, hygienic construction, and flexible configurations, it meets the needs of precision mixing processes across demanding applications.

What is the SKD Vertical Agitator?

The SKD agitator is a top-entry, direct-drive mixer engineered to handle low-viscosity products. Its vertical installation and optimized flow pattern make it ideal for small-volume tanks where complete homogenization and dispersion are essential.

Construction & Materials

– Contact Materials: AISI 316L stainless steel

– Seal System: NBR V-ring and retainer

– Bearing Support: Anodized aluminum

– Surface Finish: ≤ 0.8 µm standard; ≤ 0.5 µm available for propeller

– Optional: Sawtooth propeller, ATEX motor, motor shroud, pneumatic drive

Operation & Mixing Performance

SKD Agitators create strong axial flow by pushing fluid downward through the propeller and upward along the tank walls. They can be installed centrally with deflectors or offset to prevent rotational flow. This design ensures rapid mixing, efficient dispersion, and optimal contact of reagents or powders with the base liquid.

Ideal Applications

- Dairy (milk, cream bases)

- Food processing (syrups, sauces)

- Cosmetics (creams, gels, emulsions)

- Pharmaceuticals (suspensions, formulations)

- Breweries (fermentable liquids, additives)

Key Advantages

- High-speed agitation for low-viscosity media

- Space-saving, top-entry vertical configuration

- Full compatibility with CIP (Clean-in-Place) systems

- Multiple impeller and motor options to fit your process

- Built with hygiene and durability in mind

Frequently Asked Questions About Vertical Agitators

Q: Can I use SKD Agitators for powder dispersion?

A: Yes. With sawtooth propeller options and high-speed motors, the SKD is ideal for dispersing powders and additives.

Q: Are SKD models compatible with CIP systems?

A: Absolutely. SKD agitators are built with sanitary materials and surface finishes, making them fully CIP-ready.

Q: Is ATEX certification available?

A: Yes. We offer ATEX-certified motors for explosive environments upon request.

Call to Action

Want to improve your batch consistency and reduce mixing times? Contact TMXFLOW today for a tailor-made SKD Vertical Agitator – built for your tank, your process, and your success.

STS Twin Screw Pump – Hygienic Precision Pump for Food, Beverage & Cosmetic Industries

The STS Twin Screw Pump is a highly efficient, hygienic positive displacement pump designed for the food, dairy, beverage, and cosmetic industries. Its unique twin screw technology ensures smooth, non-pulsating flow ideal for shear-sensitive, high or low-viscosity fluids. This makes it a top choice for businesses requiring precise and reliable fluid handling solutions.

Applications

STS Twin Screw Pumps are engineered for exceptional performance across various industries:

STS Twin Screw Pumps are engineered for exceptional performance across various industries:

- Food & Beverage: Dairy (milk, cream, yogurt), chocolate, sauces, syrups, beer, and yeast.

- Cosmetics & Pharmaceuticals: Creams, gels, sterile solutions.

- Oil & Gas: Crude oil, multiphasic fluid handling, refineries.

- Chemical Industry: Corrosive chemicals, resins, adhesives.Mar

- ine & Shipbuilding: Fuel, oil, ballast, and bilge.

- Power Generation: Fuel transfer, cooling systems.

- Wastewater & Pulp: Sludge, black liquor, coatings.

Operation & Performance

Twin screw pumps use two intermeshing screws rotating in opposite directions to create sealed chambers. These chambers move axially, creating vacuum on the inlet side and pressure on the outlet side, allowing nearly pulsation-free fluid transfer.

Technical Specifications

Materials:

- Pump Casing: AISI 316 (diffusion hardened)

- Screws, Cover: AISI 316

- Elastomers: EPDM, FPM

- Seal Faces: Silicon Carbide/Tungsten

- Surface Finish: Ra ≤ 0.8

Operating Limits:

- Max Flow: 110 m³/h

- Max Pressure: 20 bar

- Temperature: -40°C to 150°C

- Max Speed: 3500 rpm

User Benefits

- 100% CIP capability at high speeds

- Single/double mechanical seals

- Dry-run capability (short periods)

- Smooth handling of abrasive or shear-sensitive fluids

- Bidirectional & totally drainable design

- Ideal for air/gas-rich products and vacuum applications

Why Choose STS Twin Screw Pumps?

Why Choose STS Twin Screw Pumps?

These pumps offer high versatility, handling a broad range of viscosities and product types with maximum hygiene and minimal maintenance. Designed for continuous, pulsation-free performance, they support both CIP and product transfer functions, reducing downtime and preserving product quality.

GET IN TOUCH FOR MORE INFORMATION

IF YOU WOULD LIKE DETAILED INFORMATION ABOUT THE STS TWIN SCREW PUMP, PLEASE CONTACT US VIA OUR INQUIRY FORM OR DIRECTLY THROUGH OUR SUPPORT TEAM.

What Are SLA Lobe Pumps? A Complete Guide for Industrial Fluid Handling

SLA Lobe Pumps offer a smart solution for energy-efficient, hygienic, and eco-friendly fluid transfer in modern industries.

How Do SLA Lobe Pumps Work?

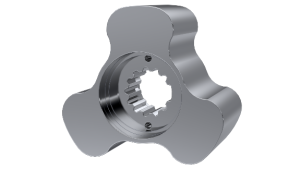

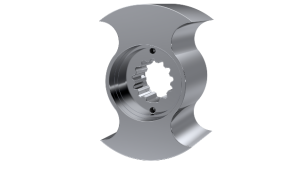

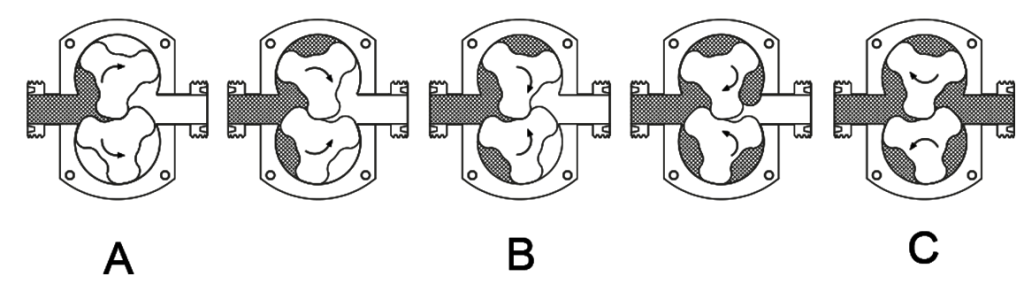

SLA lobe pumps operate using a rotary lobe mechanism where two synchronized lobes rotate inside a casing. As the lobes turn, they create expanding cavities on the suction side, drawing fluid in. The fluid is then trapped between the lobes and casing and pushed out through the discharge side.

- Non-contacting lobes (no metal-to-metal wear)

- Low pulsation flow

- Gentle handling of sensitive fluids

- Bidirectional flow (reversible operation)

Key Features of SLA Lobe Pumps

1. Hygienic & Clean-In-Place (CIP) Design

Made from 316L stainless steel, these pumps support CIP and SIP systems, making them ideal for food and pharmaceutical applications.

2. Wide Range of Viscosities

- Low-viscosity fluids (e.g., juices, milk)

- High-viscosity substances (e.g., honey, creams, syrups)Fluid

- s with delicate solids (e.g., fruit pieces, curds)

3. Energy Efficient

Designed with optimized flow paths and precision tolerances, SLA Lobe Pumps reduce energy consumption and carbon footprint.

4. Gentle, Low Shear Flow

The smooth, non-turbulent flow preserves product texture and molecular integrity — ideal for cosmetics, yogurt cultures, and bioactives.

5. Durability & Easy Maintenance

• Front-loading seals

• Modular, easy-to-disassemble design

• No need to disconnect pipework

Typical Applications of SLA Lobe Pumps

- Food & Beverage: Milk, yogurt, chocolate, sauces, wine

- Dairy: Cheese curd, cream, whey

- Pharmaceutical: Syrups, ointments, gels, vaccines

- Cosmetics: Shampoo, lotions, toothpaste

- Chemical: Paints, resins, adhesives, solvents

SLA Lobe Pumps vs Traditional Pumps

| FEATURE | GEAR PUMP | LOBE PUMP |

| PRESSURE RESİSTANCE | High | Medium |

| VİSCOSİTY COMPATİBİLİTY | Medium-High | Very High (e.g honey, cream, etc.) |

| PARTİCLE HANDLİNG | Poor | Good |

| HYGİENİC DESİGN | Generally No | Yes (CIP/SIP compatible) |

| PRODUCT SENSİTİVİTY | Low | High (gentle transfer) |

| EASE OF CLEANİNG | Difficult | Easy (especially with Tri-Clamp) |

Why “Economic” in SLA Lobe Pumps?

- Eco-Friendly: Lower energy usage, less waste

- Economical: Lower operational costs

- Efficient: Reliable flow under demanding conditions

Conclusion: Are SLA Lobe Pumps Right for You?

Discover how SLA Lobe Pumps can transform your fluid handling process with hygienic, efficient, and sustainable performance.

Understanding Lobe Pumps: Versatile Solutions for Hygienic and Industrial Applications

When it comes to transferring high-viscosity or shear-sensitive fluids with precision, lobe pumps are among the most trusted choices across a wide range of industries. From food and beverage to pharmaceuticals and chemical processing, these positive displacement pumps offer superior handling of solids, gentle product treatment, and excellent sanitary performance.

At TMXFLOW, our range of lobe pumps is designed to deliver reliable, efficient, and hygienic fluid transfer solutions tailored to your operational needs.

What Is a Lobe Pump?

A lobe pump is a type of positive displacement pump that uses two or more lobed rotors to move fluids through the pump chamber. As the rotors turn, they create expanding cavities on the inlet side, allowing the fluid to enter. The fluid is then trapped between the lobes and the pump casing and carried to the outlet, where the cavities contract to discharge the fluid.

A lobe pump is a type of positive displacement pump that uses two or more lobed rotors to move fluids through the pump chamber. As the rotors turn, they create expanding cavities on the inlet side, allowing the fluid to enter. The fluid is then trapped between the lobes and the pump casing and carried to the outlet, where the cavities contract to discharge the fluid.

Because the lobes do not touch each other or the casing, lobe pumps are ideal for handling shear-sensitive and delicate fluids without compromising product integrity.

Key Advantages of Lobe Pumps

-

Gentle Product Handling

Lobe pumps are especially suited for applications requiring low shear. They are widely used in the food, dairy, and cosmetic industries to preserve the texture and consistency of products like creams, sauces, yogurt, or gels.

-

Sanitary Design

With CIP (Clean-In-Place) and SIP (Sterilize-In-Place) capabilities, TMXFLOW’s pumps meet the strict hygiene standards required in pharmaceutical and food-grade applications.

-

Reversible Operation

The bidirectional operation of lobe pumps provides flexible installation options and easier cleaning or emptying of pipelines.

-

Solid Handling

Our pumps are capable of handling fluids with soft solids such as fruit pieces or curds, making them ideal for processing a wide range of products.

-

Durability and Efficiency

With robust construction and minimal internal friction, pumps ensure long service life and high efficiency, even under demanding conditions.

Common Applications of Lobe Pumps

- Food & Beverage: Chocolate, honey, yogurt, mayonnaise, juices with pulp

- Pharmaceutical: Creams, lotions, suspensions, syrups

- Cosmetics: Shampoo, conditioners, gels

- Chemical: Paints, adhesives, detergents, resins

- Biotechnology: Fermentation broths, cell culture fluids

Wherever precision, sanitation, and reliability are essential, TMXFLOW lobe pumps deliver trusted performance.

Why Choose TMXFLOW’s Lobe Pumps?

At TMXFLOW, we combine advanced engineering with customer-focused design to deliver high-performance lobepumps that meet both industrial and hygienic requirements. Our models are available in various configurations, flow rates, and materials to suit specific applications.

Benefits include:

- Stainless steel construction for hygienic environments

- Modular design for easy maintenance

- Multiple rotor types (bi-lobe, tri-lobe, multi-lobe)

- Customizable seals and connection types

- Competitive pricing with top-tier quality

Need Help Choosing the Right Pump?

Selecting the right pump for your process is critical. Our team of experts is here to help you find the ideal pump that fits your operational, sanitary, and budget requirements.

👉 Explore our full range of lobe pumps here

📞 Contact us today to speak with a technical specialist.

You can see detailed technical specifications in our LOBE PUMP Product Catalogue. TMXFLOW – Engineered to Move What Matters